NT SERIES ULTRA-FINE ROLLER MILL

Introduction

This is a new-type of ultra-fine grinding equipment developed by our company, combing rolling, impacting and grinding in one. It is an ideal ultrafine grinding mill for deeply processing non-metallic minerals with hardness below 7 Mosh and humidity below 6% such as calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite, kaolin, graphite, carbon black etc.

The finished product fineness can be adjusted from 325 mesh to 2500 mesh and can go through D97<5um.

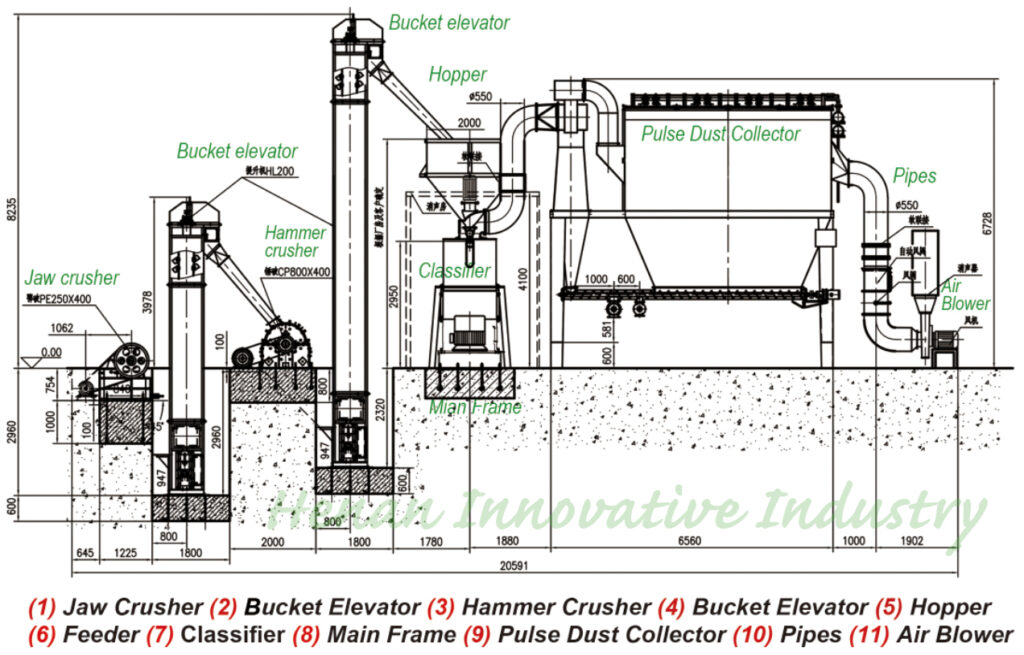

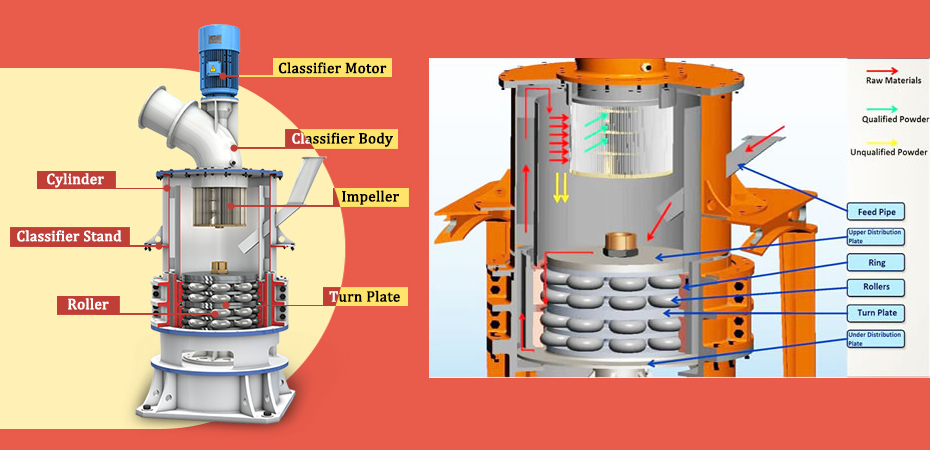

The mill is mainly consists of the feeder, main unit, classifier, pulse collector, high-pressure blower, electrical control cabinet etc.

WORKING PRINCIPLE OF NT SERIES ULTRA-FINE ROLLER MILL

Frequency-conversion feeder will feed material to the central part of upper grinding-plate evenly. The material falls to the circle under the centrifugal force and comes down to raceway of ring to be crushed into powder.

After grinded in the first raceway, the material goes to the second and third raceway. The air blower inhales the external air into the mill and carries the powder after the third grinding-plate into classifier, the classifier wheel makes the rough powder drop down and then re-grind, the fine powder will go into cyclone collector with the air flow and go down through the discharge valve as final product, meanwhile, the air with a little dust goes out through blower or silencer after purified by the dust collector.

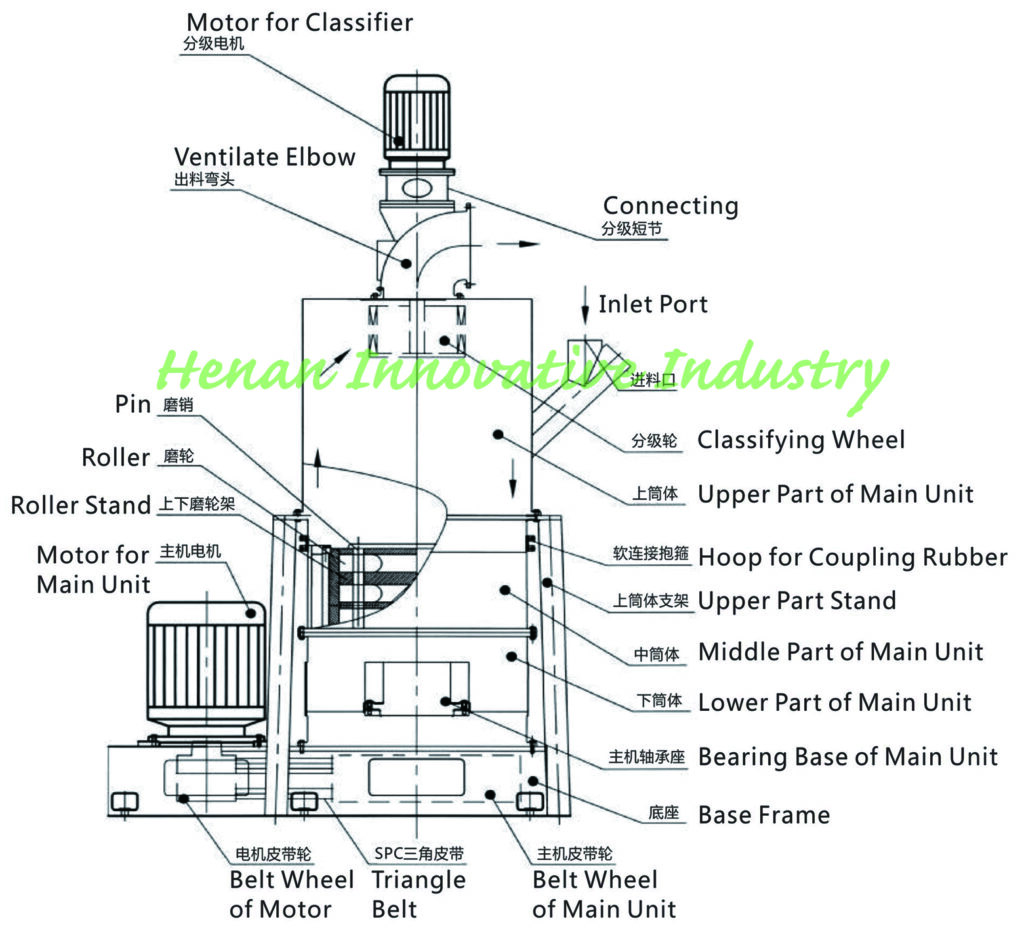

Main Unit (Grinding System)

Raw material is fed into grinding chamber via feed port of upper part, then be grinded between rollers and grinding rings into powders. Powders are blowed into upper part. Qualified particle goes into powder collecting system through classifier wheel, others fall down and grinded again.

Powder Collecting System

In reverse-pulse-jet bag-houses, individual bags are supported by a metal cage, Dusty air enters from the bottom of the bag-house and flows from outside to inside the bags. Bags are cleaned by a short burst of compressed air injection. The powder falls into a storage hopper below. This collecting system works with the help of digital sequential timer (PLC) attached to the pulse valves.

Control Panel Cabinet

Adapting domestic top level electrical components, after 20 years of testing. Our electrical control system or PLC system is very easy to operate, fully automatic operation with one button stop, It’s also easily adjustable. Buyer only needs to adjust the current and frequency with visible digitals to reach different particle size from 325-3000 mesh.

FEATURES AND ADVANTAGES

01.

Product Size and Fineness are Guaranteed

NT Series Ultrafine Roller Mill is able to reach a product fineness of 325-3000 mesh in one time. While the traditional Raymond mill can only reach maximum fineness of 400 mesh. It can be used for all kinds of grinding from rush crushing to ultrafine grinding, with the maximum fineness D97≤3um, which drives the revolution in the field of ultrafine grinding.

02.

Low Investment Cost and High Capacity Efficiency

Compared to the ball mill, air-flow mill and stirred mill, NT Series Ultrafine Roller Mill has the advantages of lower investment and shorter processing circle, and the finish product fineness/efficiency ratio is more than twice of the machines mentioned above for the same fineness.

03.

Low Investment Cost and High Capacity Efficiency

Compared to Raymond mill, NT Series Ultrafine Roller Mill has no bearing but the high-hardness wear-resistant material developed by our company within the grinding chamber, which not only avoids chronic consumption of oil and burnt bearing. but also guarantee the continuous and reliable operation of the machine.

04.

Easy Installation

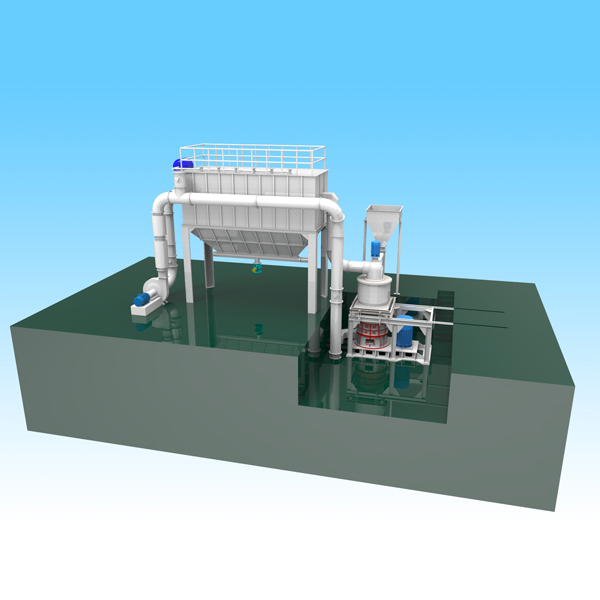

NT Series Ultrafine Roller Mill does not need large-scale construction, it covers only small area, it can be put into production as soon as finish the installation, it can run smoothly and reliably.

05.

Environment Friendly

Adopting the complete set of negative-pressure production and high-efficient off-line dust collector, the efficiency reaches up to 99.9%, which guarantees no dust pollution during the operation. Moreover, the main unit and the air blower are respectively equipped with the noise-reduction housing and the silencer so as to decrease the noise, which is completely in conformity with the national environment friendly standards.

06.

This Equipment is Sophisticated and Stable

Continuous improvements have been made within the decade since the establishment of our company; the complete machine from its materials, its processing to its assembly is completely self-produced, which forms as the benchmark for the crushing industry and becomes the one being simulated at home and abroad.

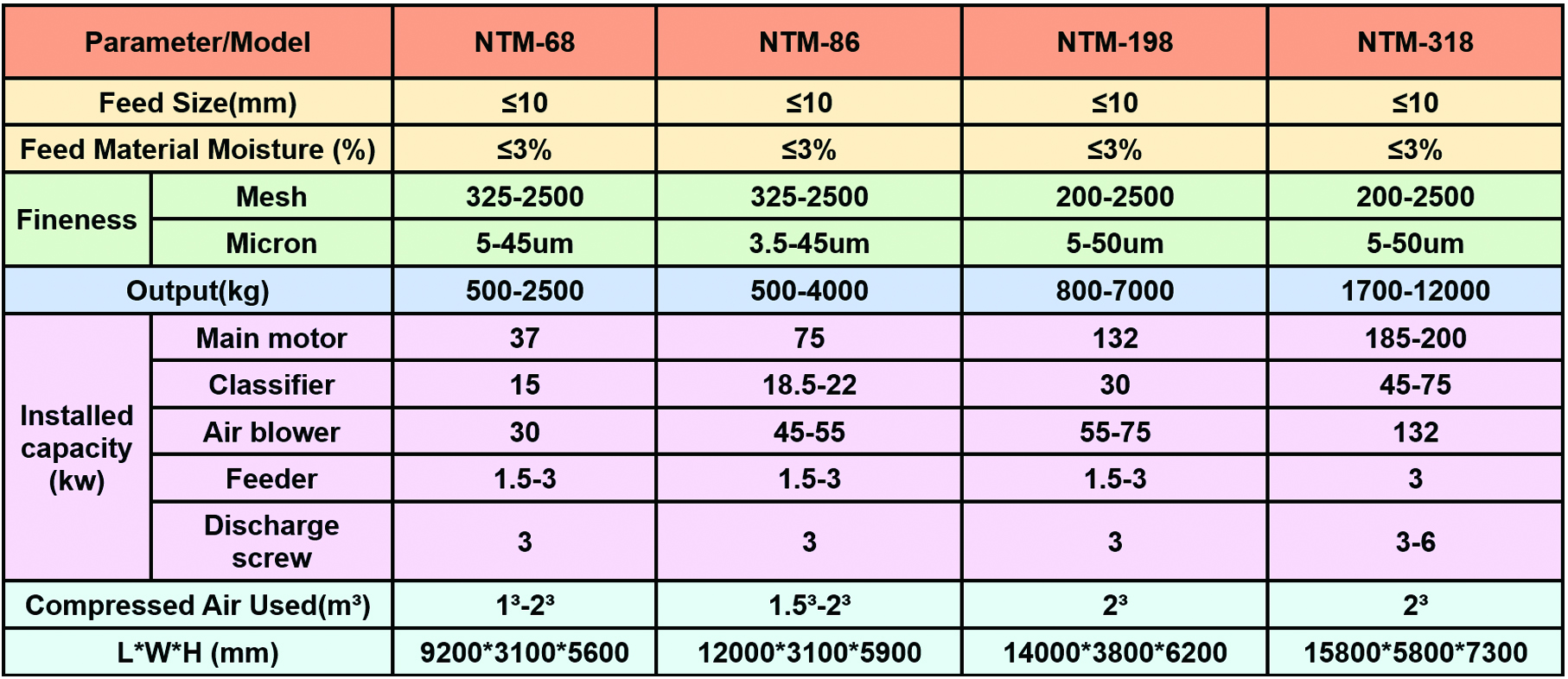

SPECIFICATION DATA

Mesh, Output Capacity and Electrical Power Consumption.

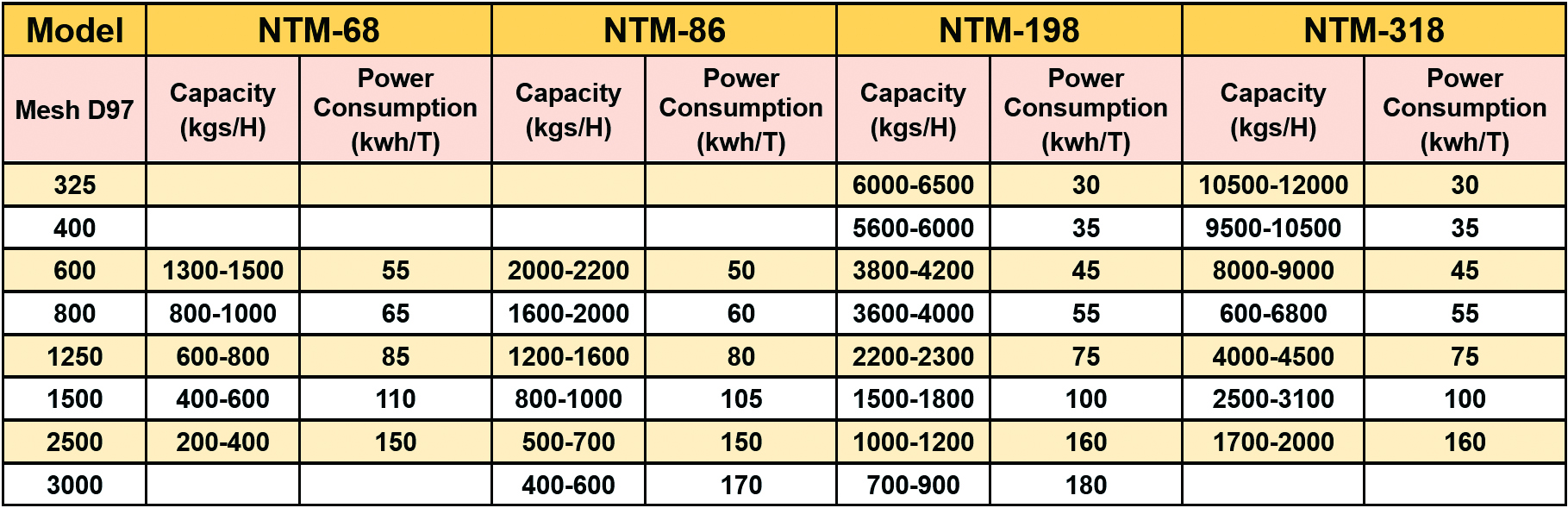

Powder Size (Mesh & Micrometer).

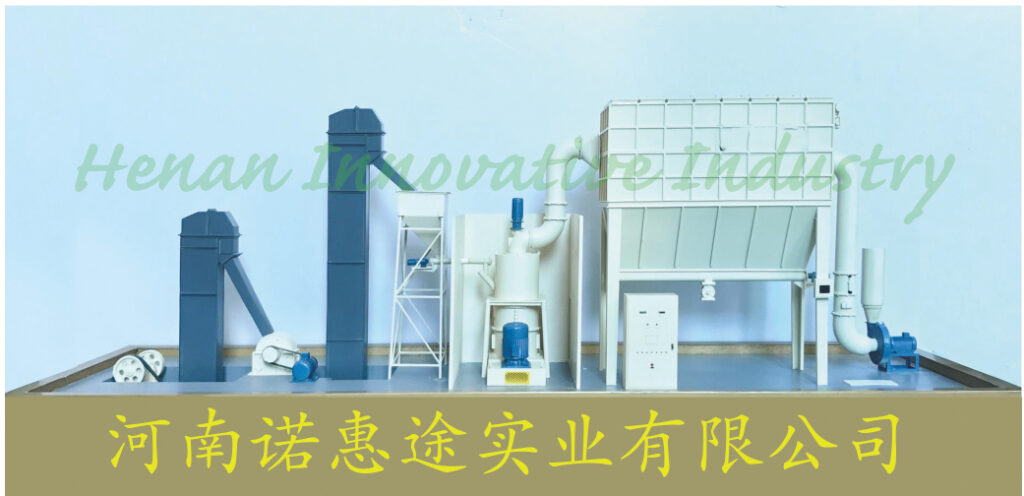

MANUFACTURING GALLERY

PROJECT IN PHILIPPINES

PROJECT IN TANZANIA

PROJECTS IN MAINLAND CHINA