Tumbler Screening Machine

Maximum screening quality for fine and ultra-fine products

INDUSTRIAL APPLICATIONS

Chemicals/Pharmaceuticals, Aggregates and Ores, Food, Waste/Recycling, Plastics, Metallurgy, Wood/Biofuels, Ceramics, Feed.

INTRODUCTION

Tumbler screening is a separation method that uses three-dimensional elliptical movement to separate very fine particles from larger ones. It is an important technique applied in many fields dealing with raw materials and building materials for process and reuse.

This technique can achieve 99% high efficiency with its circular movement. Machines with tumbler screening techniques are commonly used because of its unique rush design, high life time utility, and the flexible angular velocity the machines can achieve. However, this type of machine requires low feed flow rate and the particles size for separation have to be controlled within a specific range.

Tumbler Screening Machines TSM / tsi For Intelligent Fine Particle Screening

The highly developed genuine tumbler screening machines have set the standard for fine and ultra-fine screening technologies of all types of dry bulk material.

Modified and improved design features already successfully applied to the TSM product line are now implemented to the entire tsi product line as well. Featuring 9 different machine sizes ranging in diameters from 600 to 2600 mm Henan Innovative Industry currently offers the widest product range of tumbler screening machines available on the market worldwide.

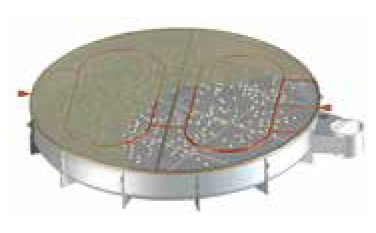

STRUCTURE AND WORKING PRINCIPLE OF TUMBLER SCREEN

Tumbler screen machine is an artificial imitation of shaking low frequency vibration sieve, working principle is synthesis of transient motion displacement and this displacement in the radial direction of the axis of circular motion (Helical motion), can adjust the eccentricity nonlinear three-dimensional motion of the exciter, the material also produces same motion approximation manual jobs, so as to achieve the purpose of screening, combined with sieving attachment can get more ideal screening effect. Suitable for circular, cylindrical, sheet, and even regular shapes easy to block network and require sophisticated screening materials.

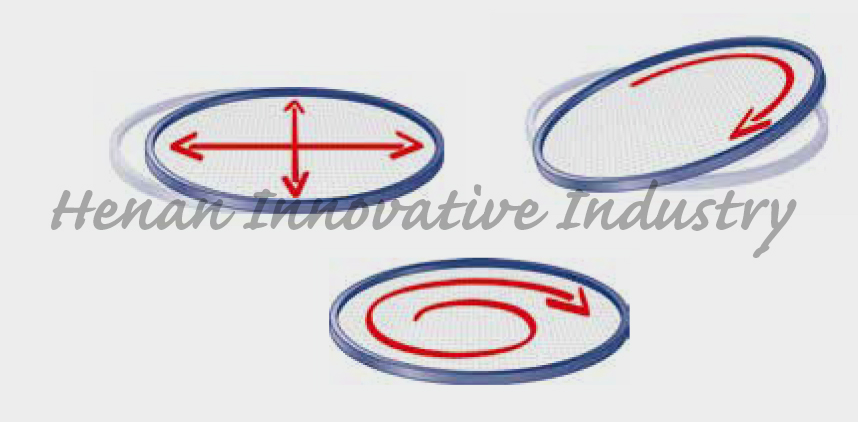

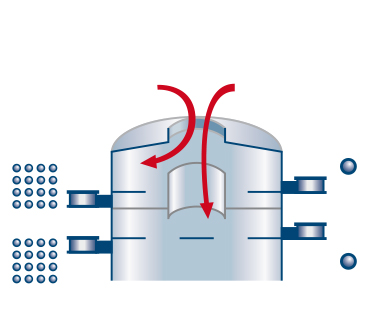

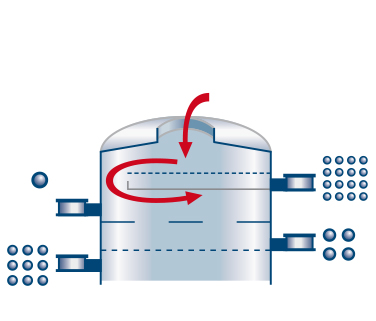

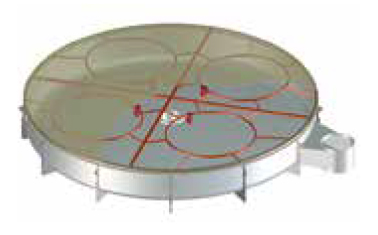

Unique tumbling type motion

The adjustment of the machine in response to the product to be screened provides an exactly defined three dimensional eccentric motion pattern with radial and tangential inclination.

During operation of the tumbler screening machine the radial inclination causes the product on the screen to move from the center towards the edge of the screen while the tangential inclination leads to a circular motion of the product on the screen. The combined impact of both of these forces causes the product in a helical motion of upon the surface of the screen and therefor to a relatively long retention time. This provides an optimized result on fraction separation while at the same time minimizing the amount of remaining outsize particles.

01.

Internal screen inserts featuring replaceable slip-over edge sealings

02.

Machined screen frames equipped with O-Ring gasket i.e. for the pharmaceutical industry.

03.

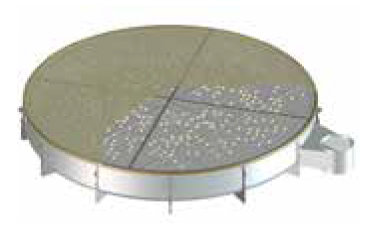

Fully segmented screen inserts optional with ultrasonic screen cleaning devices.

04.

Mild steel and various stainless steel machine models.

05.

Surface qualities ranging from glass beaded via grinded versions all the way to electrically polished finish.

06.

Food grade elastomer parts (i.e. sealings, covers, etc.).

07.

Food grade glue for mesh cloth fixation on the screen frames

08.

Manual or pneumatic deck lifting devices.

09.

Various mesh cleaning systems (ball-, ultrasonic-, air- and brush cleaning devises as well as combined cleaning systems).

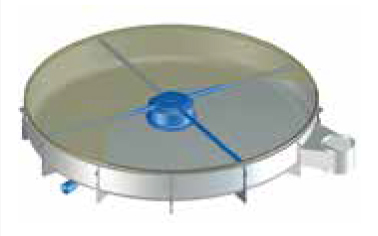

OPTIMIZED MULTIPLE DECK COMBINING SYSTEM FOR MAXIMUM PRODUCTIVITY

Maximizing the screening process performance and -quality by combining optimized selected screen deck modules.

This pays back quickly, particularly when handling high-quality bulk materials, since the proportion of oversize or under-size particles in the various fractions will seriously be reduced.

In addition to the examples shown here, Henan Innovative Industry provides a large scale of further machinery combinations for almost any given application.

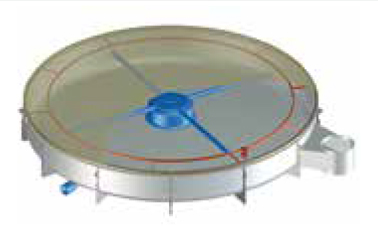

Double screening machine DS

The screening in two fractions with two decks of the same screen mesh aperture lead to a maximum recovery of the fine product.

Double screening machine with Pre-screening DS+1 (2)

The number of fractions produced by a DS screening machine can be increased by adding one or two coarse screens on top.

Double capacity screening machine DL

When screening in two fractions only, the output can almost be doubled by using a DL machine instead of a single deck machine.

Two stage screening machine for reversed screening DSU

The fine material will be removed first while the coarse material is acting as a cleaner and improves this way the classification of the fine material.

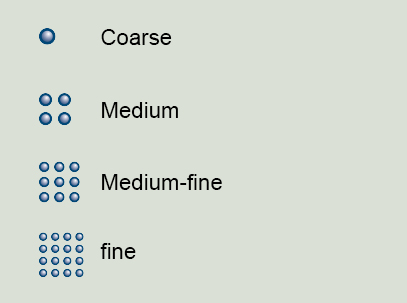

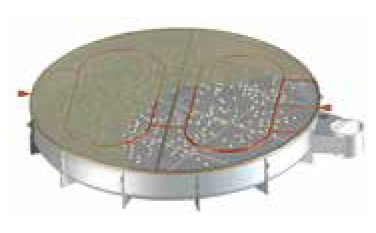

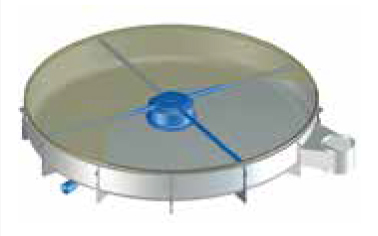

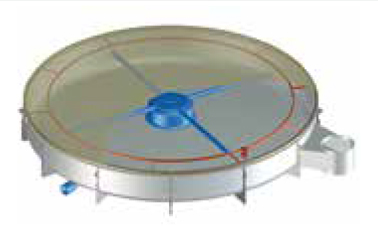

CONTINUOUS MESH CLEANING GUARANTEES HIGHEST SCREENING QUALITY

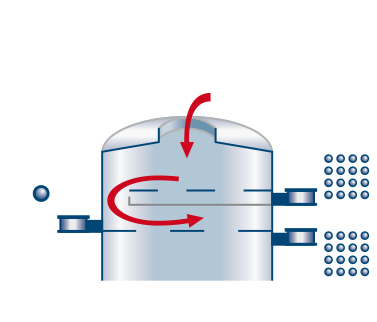

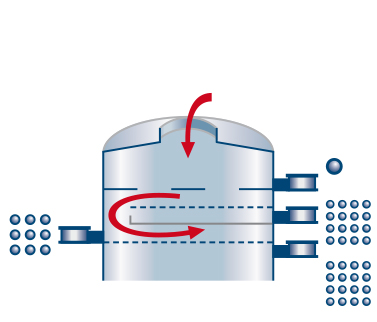

Due to its round body and its unique drive system the tumbler screening machines are particularly suitable for operating with various types of mechanically driven rotating mesh cleaning devices.

The screen is continuously cleaned during the screening process ensuring high screening quality and a constantly high product flow.

Bouncing balls

The bouncing ball mesh cleaning device available in several variations is the universal cleaning system for numerous granular products.

Ultrasonic

Ultrasonic screen cleaning is particularly suitable for applications with fine mesh apertures ranging from 20 to 1,000 μm.

Combined ultrasonic and balls

For a maximum of product throughput through the screen and permanent mesh cleaning.

Air Flow

The impact of high speed air flow provided by rotating arms placed directly under the screen is blowing out particles caught in the mesh which is an ideal solution i.e. for sticky products.

Combined ultrasonic and air

Applicable when processing products extremely critical to screen such as fine plastic powders etc.

Conical rolling brushes

Rotating conical brushes placed right under the screen clean gentle and with low-wear. Typically used for spherical products blinding the mesh.

Combined air and brushes

This is an effective cleaning system.

i.e. for greasy or electrostatically charged products.

Passing/straining unit

Allow gentle straining i.e. dis-agglomeration of products like instant coffee by using steel or plastic spatulas, rotating on top of the screen.

TECHNICAL ADVANTAGES AND FEATURES

01.

Screening efficiency up to 99% achievable. Throughput of up to 40 t/h

02.

No particle destruction of sensitive products due to gentle screening.

03.

Higher specific screening performance in comparison to purely vibrating systems due to higher screening amplitude.

04.

Stable screen motion even at full load.

05.

The steplessly adjustable tumbling motion enables precisely controlled particle retention of the product on the screen enabling screening capacity and efficiency to be balanced to the optimum.

06.

The three dimensional screen motion can easily be recorded enabling reproducible operating conditions to provide a constant high product quality.

07.

Large variety of product specific mesh cleaning systems are available.

08.

Rapid screen replacement systems optionally available.

09.

Modular elements system allow multiple machine concept variety.

10.

Dust-proof construction, even gas tight machine models available.

11.

Low noise and low vibrating operation.

12.

Maintenance friendly. Up to 100% availability in 24h operation with few maintenance requirements.

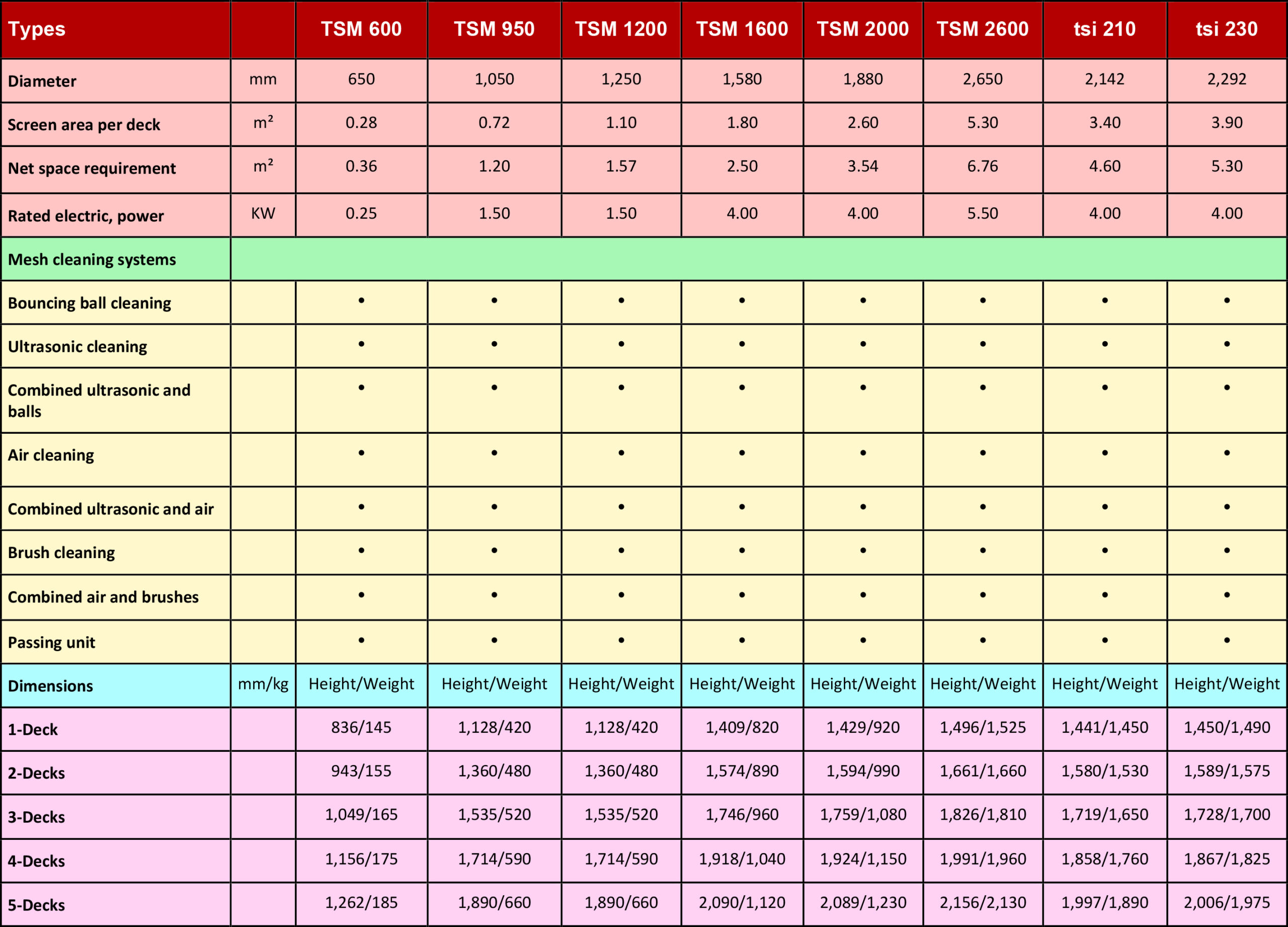

SPECIFICATION DATA