Stone Crusher

Introduction

Application Fields: Metallurgy, Chemical, Building Materials, Electricity, Transportation and other Departments.

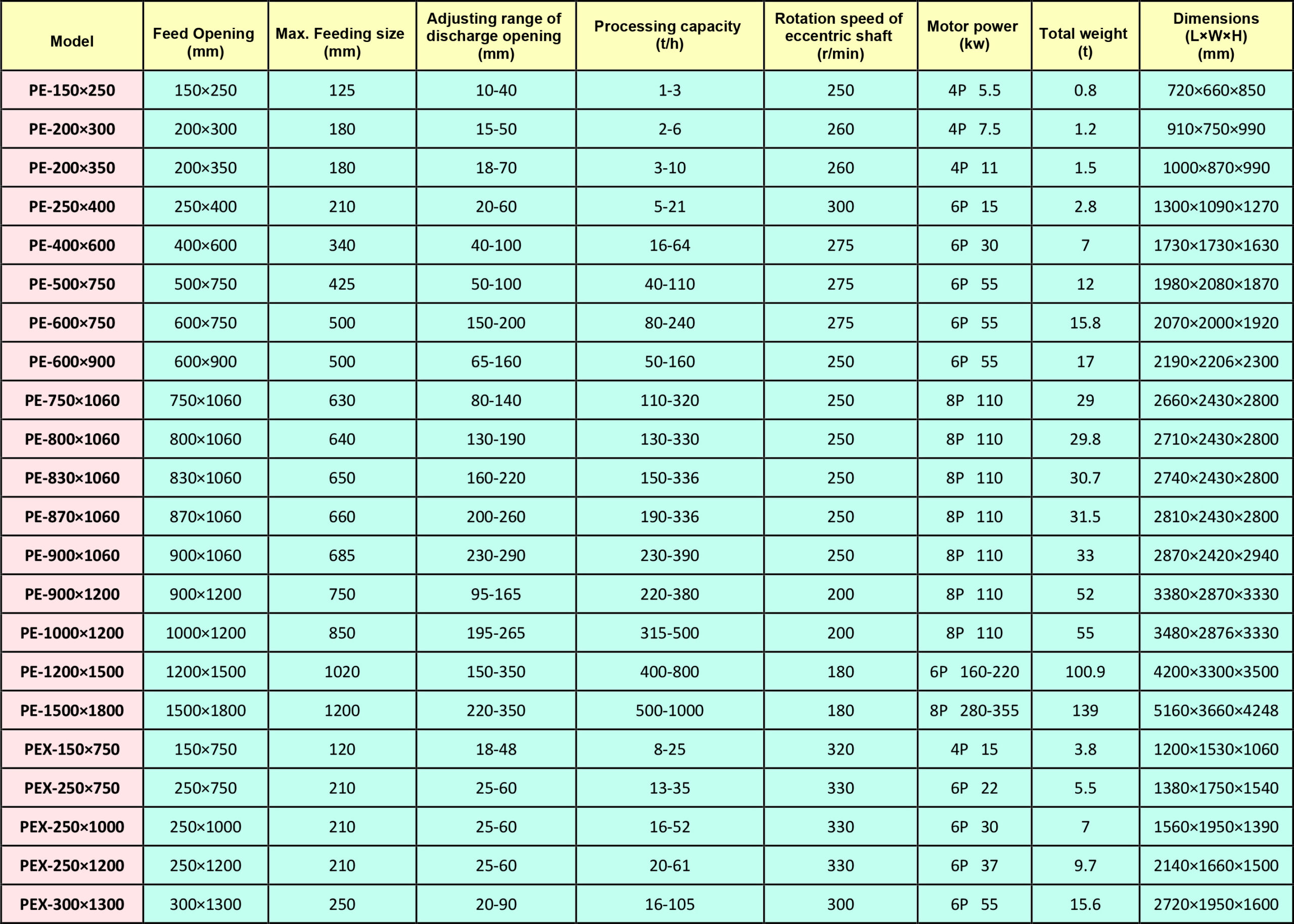

Processing Capacity:

5-1000 t / h

Feeding Size: 125-1200 mm

FLOW-CHART PROCESS

Stone raw material with large blocks is evenly fed into a stone crusher to be crushed primarily. The primarily crushed stone is sent into a cone crusher by a belt conveyor to be crushed further. With a belt conveyor the finely crushed stone is sent into a vibrating screen to be screened into gravel with different particle sizes. The gravel with qualified particle size will be sent to the final product pile by the belt conveyor while the one with unqualified size will be sent into the cone crusher by the belt conveyor to be crushed again. The finely crushed stone will be sent into the vibrating screen by the belt conveyor to be screened into gravel with different particle sizes.

Similarly, with the belt conveyor, the qualified gravel will be sent to the final product pile while the unqualified one to the cone crusher to be crushed again, which forms a closed circulation for many times. Besides, it can be equipped with a dust collection equipment for the requirement in environmental protection.

TECHNICAL ADVANTAGES AND FEATURES

01.

Unique Flywheel Design

Reduce vibration effectively, Machine work is stable.

02.

Large Crushing Ratio

Low suspension motion mechanism leads to greater crushing ratio.

03.

Easy to Maintain

Application of high wear-resisting toothed plate, long maintenance period, and cost-saving.

04.

Low Failure Rate

Reliable performance, optimized design, the low failure rate.