SCREW CONVEYOR

Introduction

Application Fields: Suitable for various industries such as building materials, chemical industry, electric power, metallurgy, coal mining and food etc…

Processing Materials: Applicable for conveying powder, granules and small lump materials block in horizontal or oblique such as cement, fly ash, pesticides, titanium dioxide, paint, etc.. The material temperature is less than 200 ℃. Screw conveyor is not suitable for transportation of perishable, high viscosity, or easy to agglomerate materials.

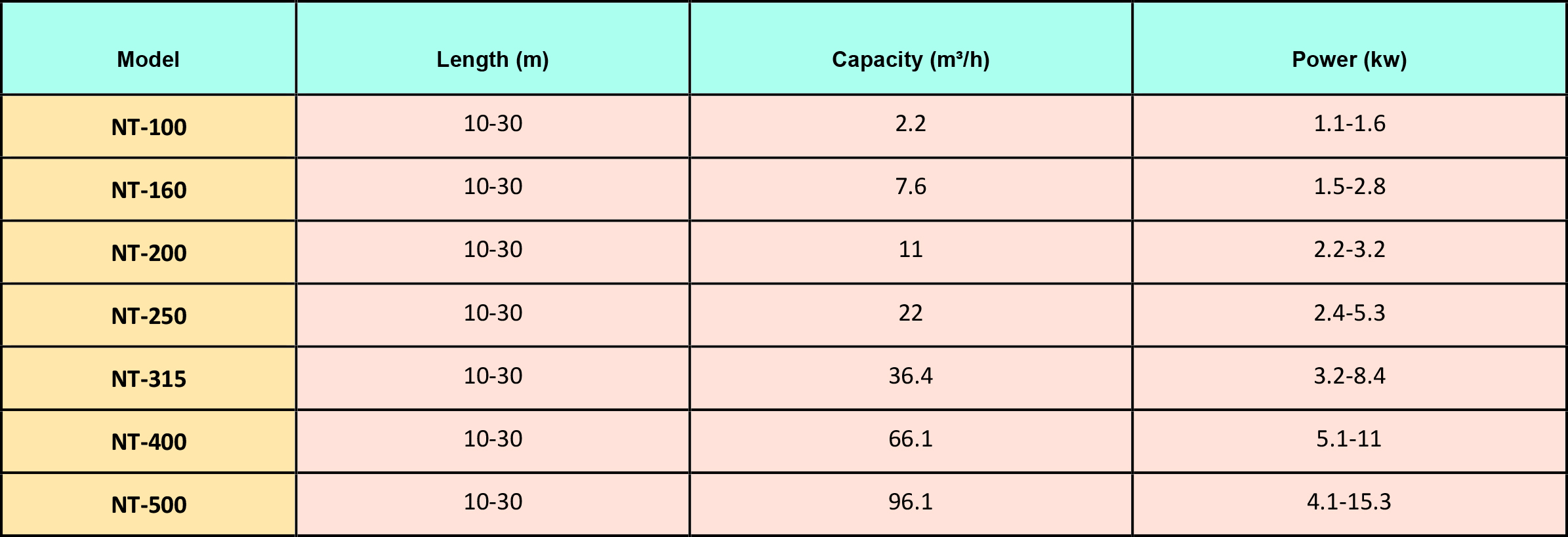

Conveying Distance : 10 ~ 30 m

Conveying Capacity : 2.2 ~ 100 m³/h

Motor Power : 1.1 ~ 15.3 Kw

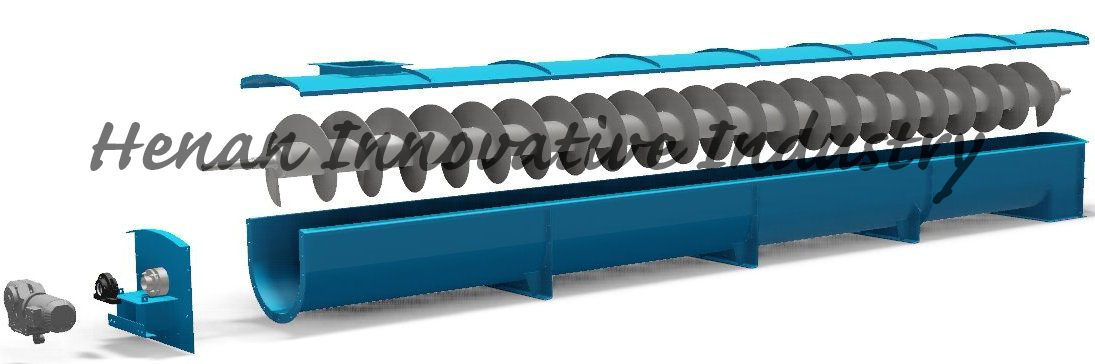

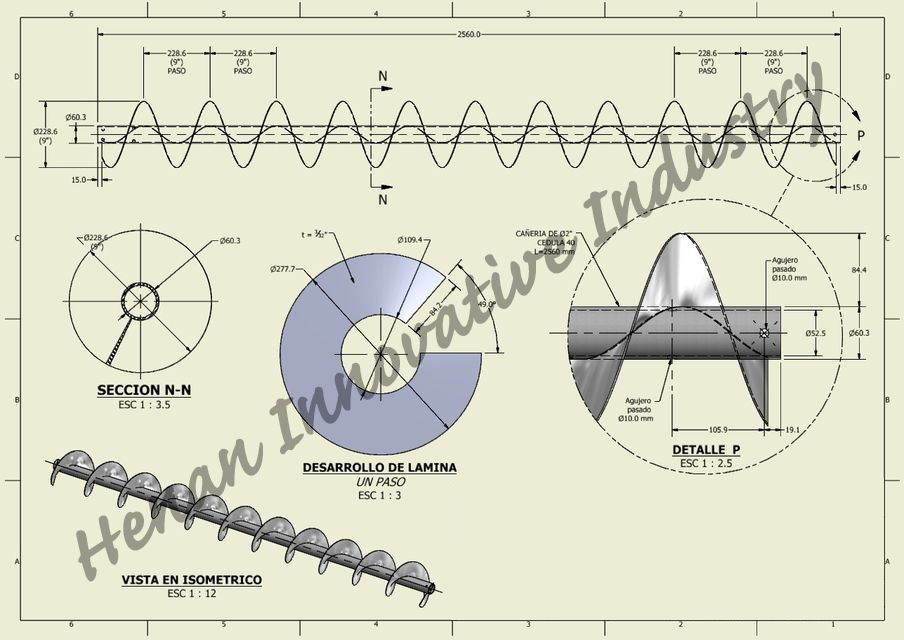

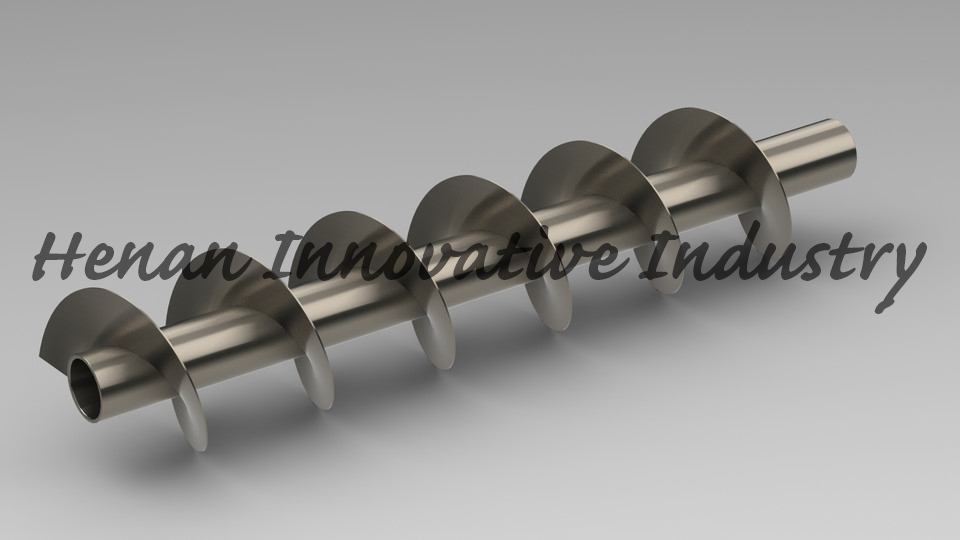

Screw conveyors are conveyor systems for bulk materials that are based on the operating principle behind Archimedes’ screw. The conveying element in these conveyors consists of flat metal shaped into a helix (screw spiral). This helix rotates around the system’s longitudinal axis and conveys bulk material in an axial direction inside a stationary trough or tube (which simultaneously acts as a carrying element).

The material being handled can be conveyed horizontally, diagonally, and vertically. In addition, processing activities such as mixing, de-watering, and compression can be performed while the bulk material is being conveyed, and the latter can also be cooled or dried during the process. Screw conveyors feature a simple design, but are only useful for relatively short distances. Also, due to the friction exerted by the bulk material inside the screw conveyor trough, screw conveyors require significantly more power than belt conveyors and bucket elevators.

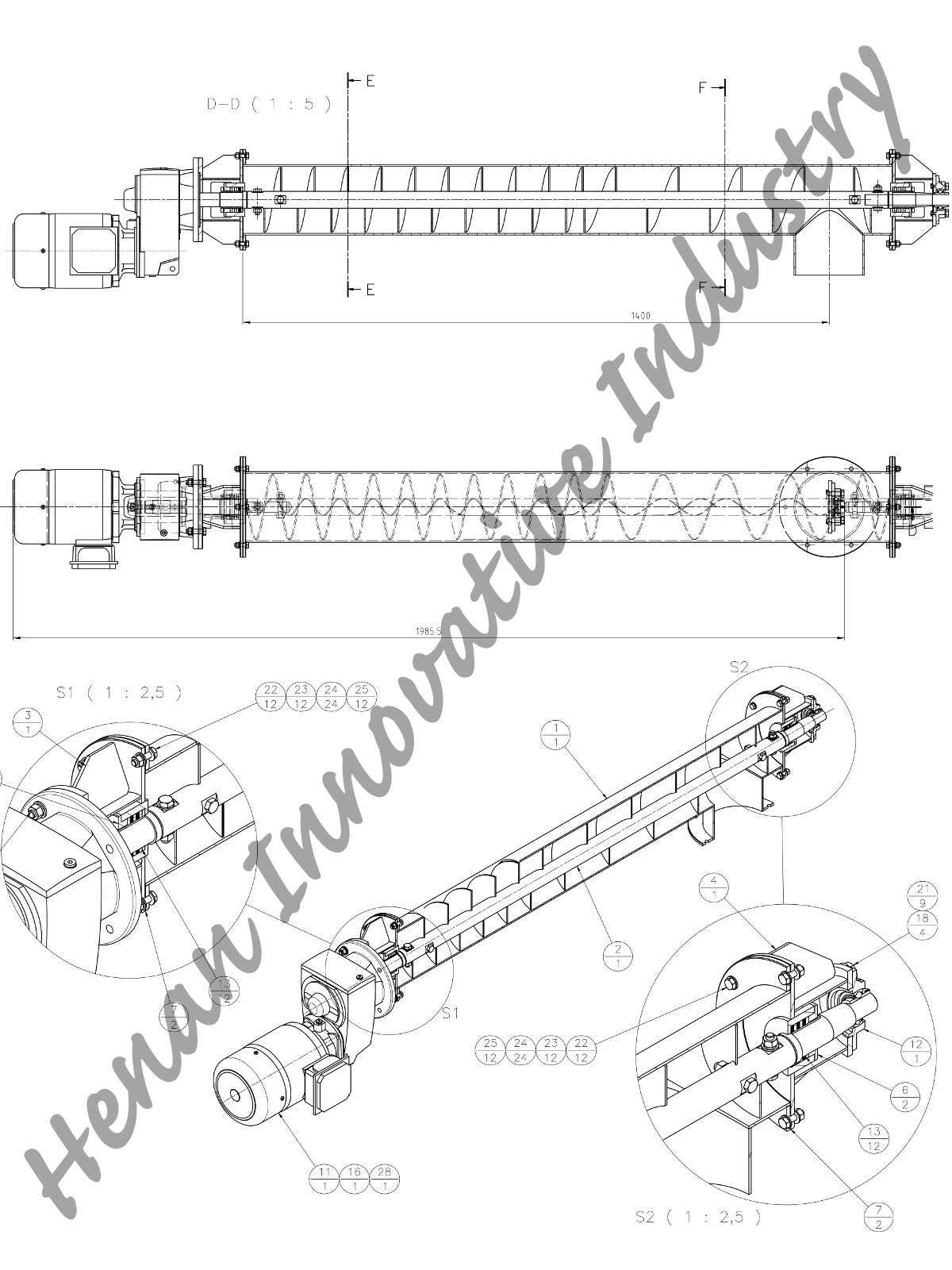

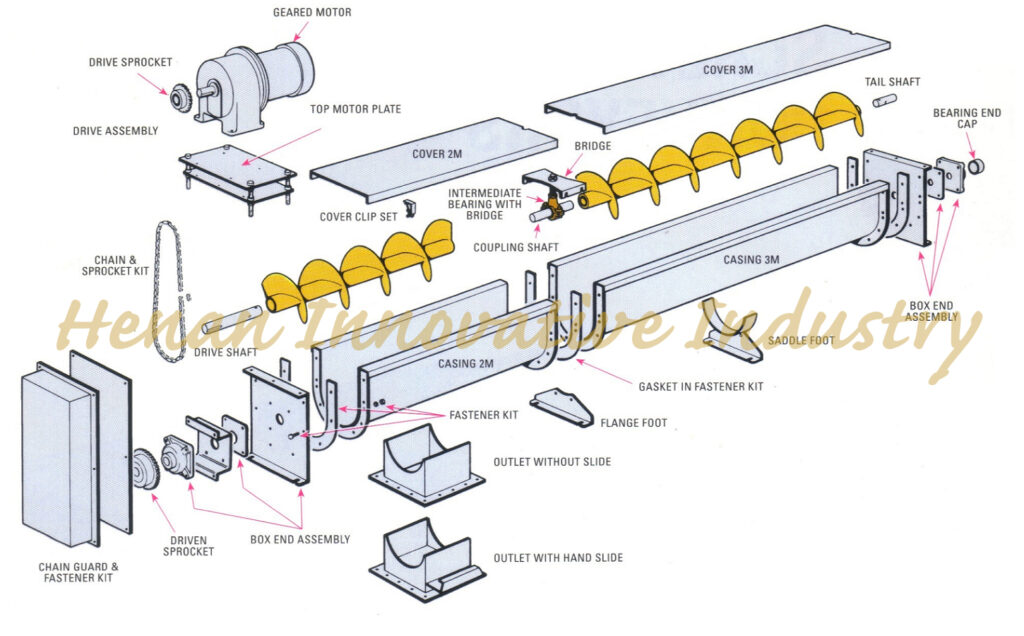

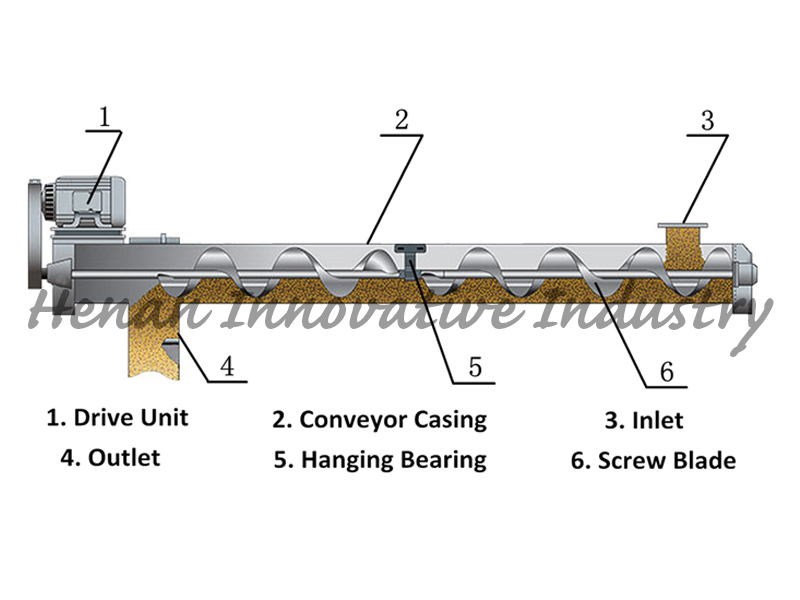

STRUCTURE & WORKING PRINCIPLE OF SCREW CONVEYOR

When the screw shaft is rotating, due to the gravity of the material and the friction between the materials and the wall, it makes the material moving forward along the conveyor bottom under the push of the blade.

It looks like an un-rotatable nut does translational movement along the rotating screw. The materials movement at the mid bearing is pushed by the moving-forward materials from back. Therefore, the materials delivery inside the conveyor is like a kind of slip movement.

To have the screw shaft under better pulled state, normally have the motor and discharging port at same side of the screw conveyor. And have the outlet at the other end of screw. The screw blade pushes the materials to realize materials-delivery. Because of the materials gravity and also the friction between the materials and shell, the materials will not rotate together with the screw. The screw blade surface type according to the to-be-conveyed materials, it can be: entity type, belt type, and leaf surface type.

The screw shaft of the Screw Conveyor is with thrust bearing at the end of the materials moving direction to give the screw shaft reverse force together with the materials. When it is comparatively long, then mid hanging bearing is required.

TECHNICAL ADVANTAGES AND FEATURES

01.

The Spiral conveyor has a simple structure, convenient maintenance and low cost.

02.

The conveying volume is large and the conveying distance is long.

03.

Low noise, stable delivery, standard spare parts.

SPECIFICATION DATA