Bucket Elevator

Introduction

A bucket elevator, also called a grain leg, is a mechanism for hauling flowable bulk materials vertically.

Application Fields: Powders And Granules.

Processing Materials: Limestone, coal, gypsum, clinker, dry clay, cement, stones, sand, clay, ore, etc.

Lifting Height: 25-40m

Conveying Capacity: 7-150 m³/h

Max. Size: 15-75mm

Bucket elevator is a kind of conveying machine, bucket elevator usually uses a series of buckets which are uniformly fixed to the endless traction chain or belt to continuously lift bulk or broken materials in or near the vertical direction. Bucket elevator is suitable for lifting convey from low to high. The conveying speed can be adjusted according to the transmission volume, and the lifting height can be selected as needed.

Henan Innovative Industry has been building custom bucket elevators for over 15 years. We offer a variety of bucket elevator designs and sizes to handle materials ranging from dry dusty powders such as fly ash, to heavy materials such as iron ore pellets. Bucket elevators can be ordered in a number of configurations, including centrifugal belt, centrifugal chain, continuous belt, continuous single chain and continuous double chain.

The bucket elevator is suitable for conveying coal, cement, stone, sand, clay, ore and other powder, granular and small lump materials with non-grinding and small grinding. Due to the traction mechanism of the circular chain, the bucket elevator can transport the materials with higher temperature (The high temperature of materials can not exceed 250 ℃).

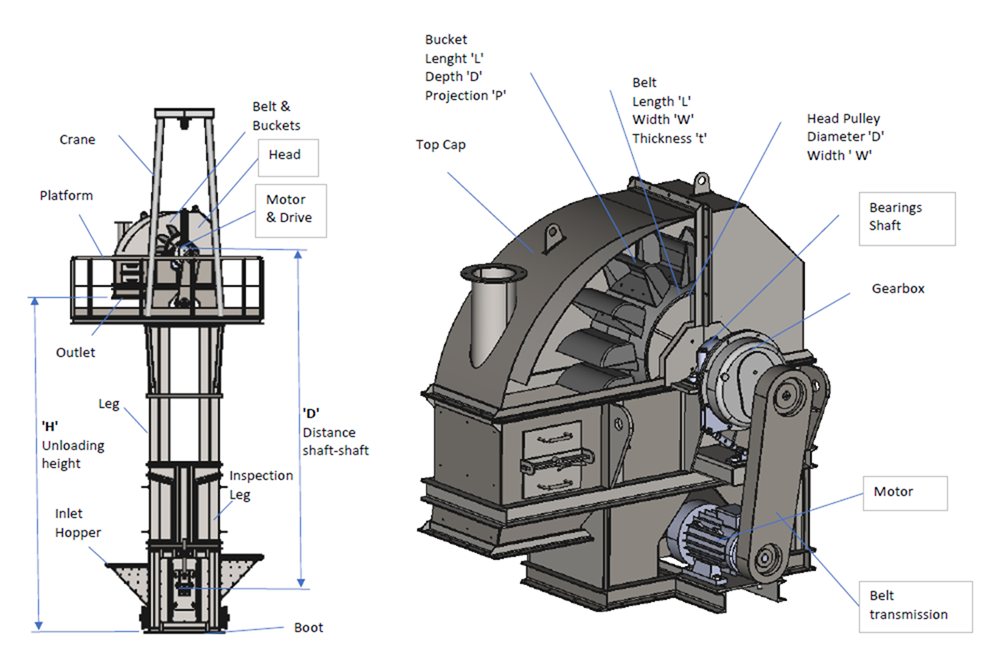

Bucket elevator has a large transmission capacity and a high lifting height. It is suitable for lifting materials from the low to the high. After the supplied materials are put into the hopper through the shaking table, the machine automatically and continuously transports the materials up. And according to the transmission capacity, it can adjust transmission speed, and choose the lifting height to meet the need. The bucket elevator mainly consists of shell, traction (conveyor chain), hopper, driving wheel (main wheel), bend wheel (tail wheel), tensioning device, guiding device, feeding port (inlet), discharging port (outlet) and other components.

STRUCTURE & WORKING PRINCIPLE OF BUCKET ELEVATOR

The bucket elevator is mainly composed of traction parts, buckets, driving device, head, barrel, base and so on.

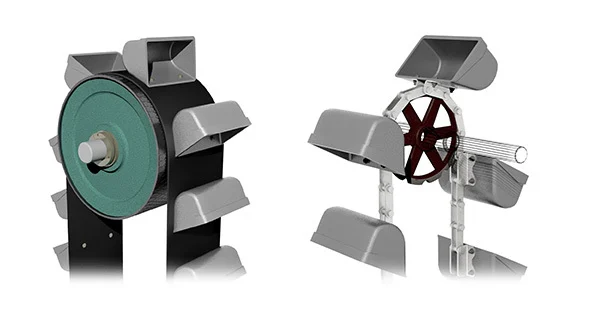

Traction Parts: There are 2 kinds of traction parts: belt and chain. Belt is generally divided into cotton rubber belt, nylon belt, steel belt. The chain mainly includes HL, forged ring chain, forged square chain as well as plate chain.

Buckets: Carbon steel, stainless steel and polypropylene materials can be selected according to material characteristics.

Driving Device: The driving device consists of drive drum (or sprocket), motor, reducer, coupling, backstop and driving platform.

Head: It is composed of head wheel, head shell, discharge port and transmission device. The bucket elevator will install an anti-reverse device on the head wheel shaft to prevent material blockage caused by equipment failure in the process of operation.

Base: It is made of machine base shell, bottom wheel, tensioning device, feed hopper and induction devices.

The bucket elevator working principle is relatively simple, mainly relying on the bucket hoppers fixed on the chain (belt) to lift the materials flowing evenly into the tail feed port from the tail of the bucket elevator to the head of the bucket elevator uninterruptedly, and then unload the materials from the head outlet to complete the whole lifting process of the materials.

Bucket elevator is suitable for lifting from low to high, the lifting height can reach 40 meters. Bucket elevator is generally equipped with casing to prevent flying dust.

NT - NE Series Bucket Elevator Structure

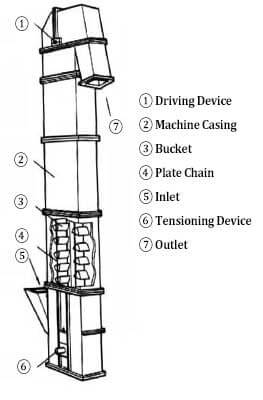

NE series bucket elevator is composed of traction plate chain, driving device, upper section, middle casing, hopper and lower section.

NE series bucket elevator drive device according to the structure form is divided into motor + reducer form and planetary cycloid gear reducer form two structures. According to the layout position is divided into left and right installation of two layout position.

NE series bucket elevator middle shell is divided into two kinds of guide rail and no guide rail. According to the length is divided into standard middle casing and non-standard middle casing. The lower section is tightened by the weight box. After installation, fill the box with heavy objects.

Chain bucket elevators provide a higher-capacity, more durable handling option. They are best for jobs requiring rugged handling of large particles, or materials that are heated or have a potential for combustion.

NT - NE Series Bucket Elevator Performance Characteristics

Wide range of use

This type of hoist has low requirements on the type, characteristics and particle size of materials. Not only can improve the general powder, granular and massive materials, but also can improve the grinding of large materials. Temperature for materials ≦250ºC.

Large conveying capacity

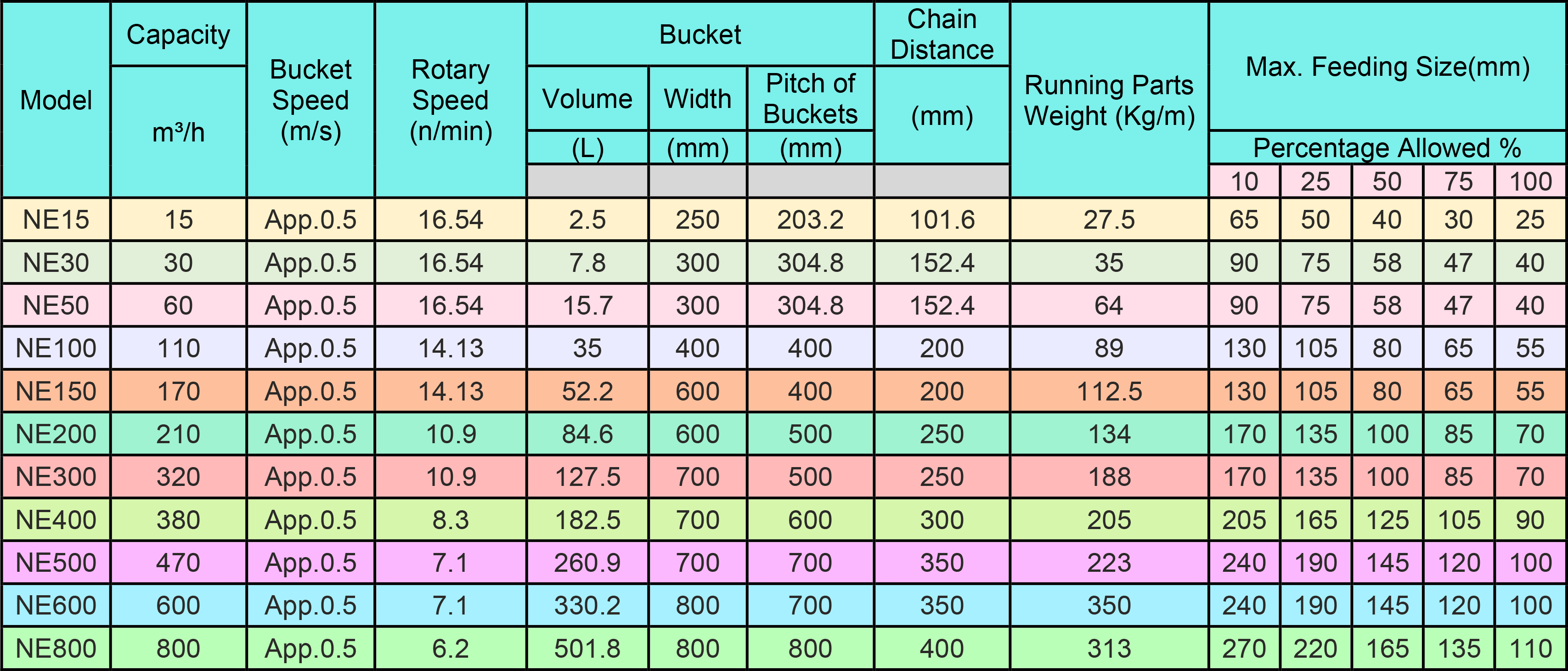

This type of elevator has more than NE15 ~ NE800 models. Compared with other types of elevators with the same amount of lifting, the mechanical size of this type of elevator is smaller, and the lifting range is 15 ~ 800m3/h.

The drive power is small

NE hoist adopts inflow feeding, gravity induced unloading, hopper adopts intensive continuous layout, chain speed is low, the amount of lift is large, ineffective power is less, reduce the drive power.

High lifting height

NE hoist chain speed is low, smooth operation, and the use of plate chain, can reach a higher lifting height, lifting height can reach 40m.

TECHNICAL ADVANTAGES AND FEATURES

01.

Small power for operation

It adopts inflow feeding, inducement discharging, large-capacity and hopper-intensive layout. In the process of lifting materials, there is almost no back feeding and digging phenomenon, so the utilization rate of power is high.

02.

Wide range of applications

Bucket elevator has less demands on the variety of materials and features. It can lift not only the general powder and small granular materials, but also the grinding materials.

03.

Smooth operation, reliable work

Advanced design principles and processing methods ensure the reliability of the whole operation, which makes the trouble-free time more than 20,000 hours.

Simple operation, easy maintenance, no environmental pollution, large transmission capacity, and high lifting height.

04.

Long service life

The adoption of inflow feeding makes few phenomena of squeezing and collision between the materials. The design of the machine ensures that in the process of materials feeding and discharging, there is little scattered, which reduces the mechanical wear.

SPECIFICATION DATA