LINEAR VIBRATING SCREEN

Introduction

Application Fields: Widely used in mining, coal, smelting, building materials, refractory materials, light industry, chemical and other industries.

Applicable Materials: Titanium iron powder, mineral powder, quartz stone, clay, copper ore, basalt and other materials.

Processing capacity: 75 ~ 1300 m³/h

Feeding size: 0.074 ~ 15 mm

Number of sieve layers: 1-6

Angel: 0 ~ 7°

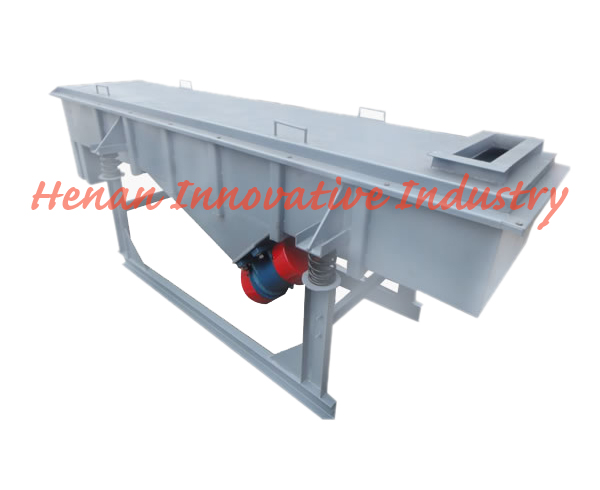

NT-SZF linear vibrating screen uses vibration motor excitation as a vibration source to cause the material to be thrown up on the screen while moving forward in a straight line. The material enters the feeding port of the screening machine uniformly from the feeder, and several kinds of sieve tops and sieves are produced through the multi-layer screen, and are respectively discharged from the respective outlets. Suitable for assembly line operations.

STRUCTURE & WORKING PRINCIPLE OF LINEAR VIBRATING SCREEN

NT-SZF linear vibrating screen is mainly composed of vibrators, screen box transmission devices, vibration isolation devices and other components.

The linear vibrating screen is driven by a double vibration motor. When the two vibration motors are synchronized and reversely rotated, the exciting forces generated by the eccentric blocks cancel each other in a direction parallel to the motor axis, and are combined in a direction perpendicular to the motor shaft, so that the movement of the sieve machine It is a straight line.

The two motor shafts have an inclination angle with respect to the screen surface. Under the combined force of the excitation force and the material self-gravity, the material is thrown up and jumped forward in a linear motion on the screen surface. Thereby achieving the purpose of screening and grading materials.

FEATURES AND TECHNICAL ADVANTAGES

01.

Stable, low consumption, low noise, long lifespan, durable vibration and high efficiency.

02.

The design of screen is very exquisite and easy to install, just need one person to operate.

03.

Big screening area and high capacity.

04.

Special screening structure, and it is very easy to change (just 3 to 5 minutes), also we can use various materials, such as nylon, PP net.

05.

The main net can support fine net, so that fine net has long lifespan, which can extend the lifespan and lower the cost.

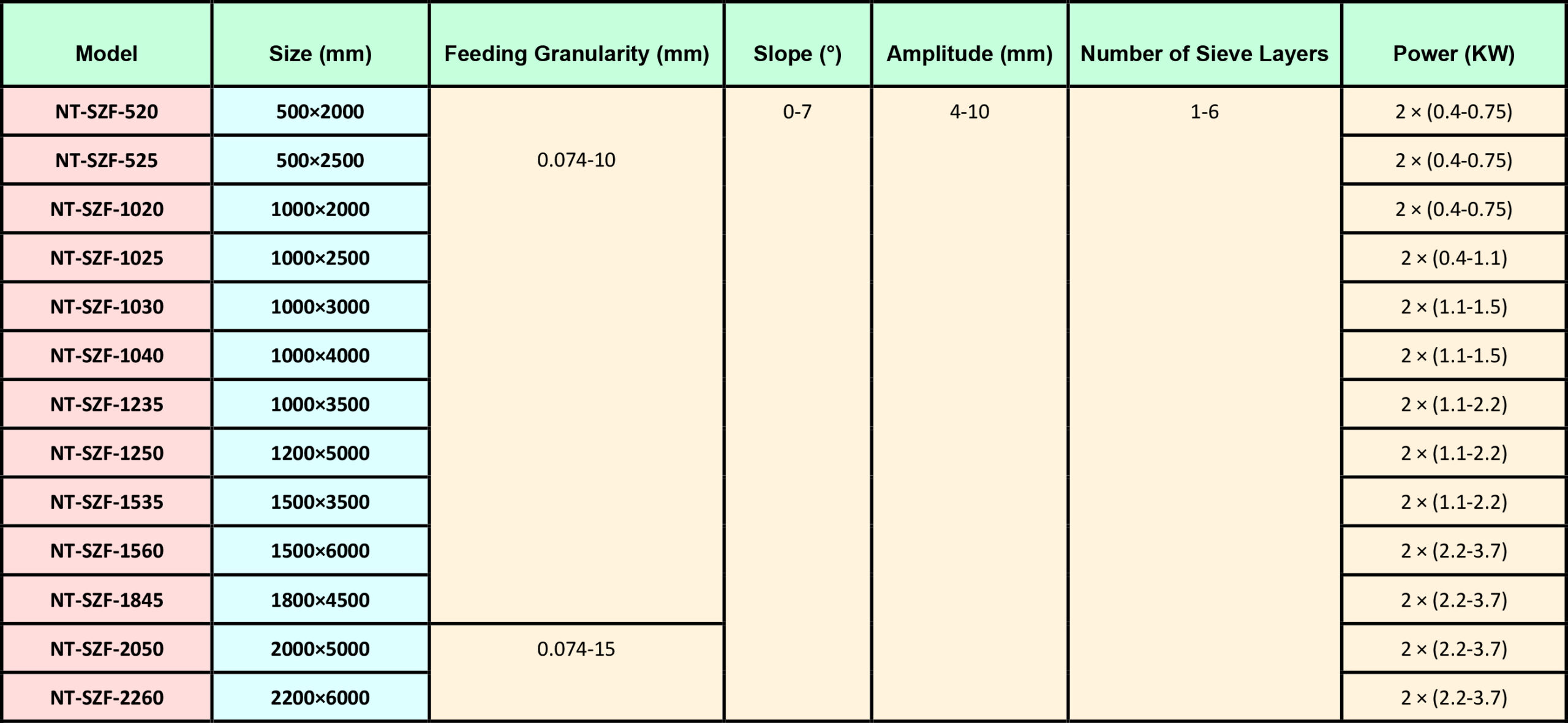

SPECIFICATION DATA