LIME STONE SOLUTION

Rotary Kiln

Introduction

Application Range: In the production industries of building materials, metallurgy, chemical industry and environmental protection, rotary kiln is widely used for mechanical, physical or chemical treatment of solid materials.

Application Materials: Cement, Lime, Refractories, Metakaolin, Titanium dioxide, Alumina, Vermiculite, Iron ore pellets.

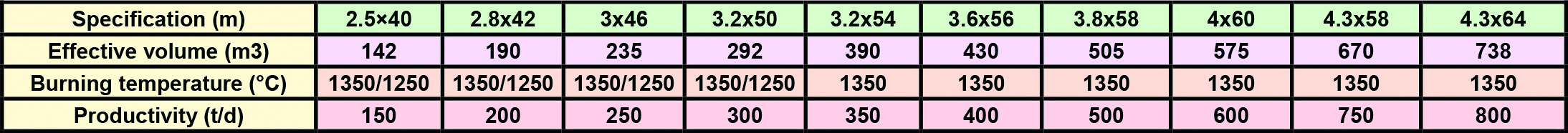

Production Capacity: 5.5~350 t/h

Kiln Speed: 0.125~5.0 r/min

A rotary kiln is a pyro-processing device used to raise materials to a high temperature (calcination) in a continuous process.

Rotary kiln refers to rotary calciner, belongs to building material equipment. It can be divided into cement rotary kiln, metallurgy rotary kiln and lime rotary kiln.

Cement rotary kiln is mainly used to calcine cement clinker, it can be divided into dry process and wet process. Metallurgy kiln is mainly used to calcine lean iron ore, bauxite, aluminium hydroxide, chrome ore etc. Lime rotary kiln is used to calcine active lime and light burned dolomite used in steel plants and ferroalloy Factory.

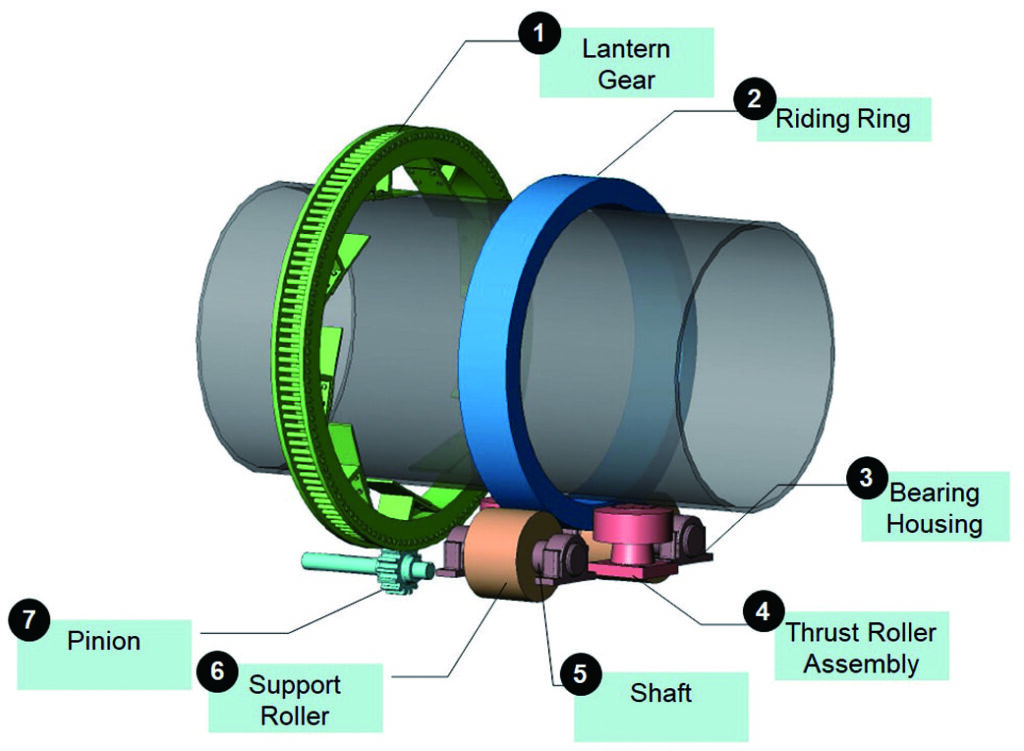

ROTARY KILN STRUCTURE

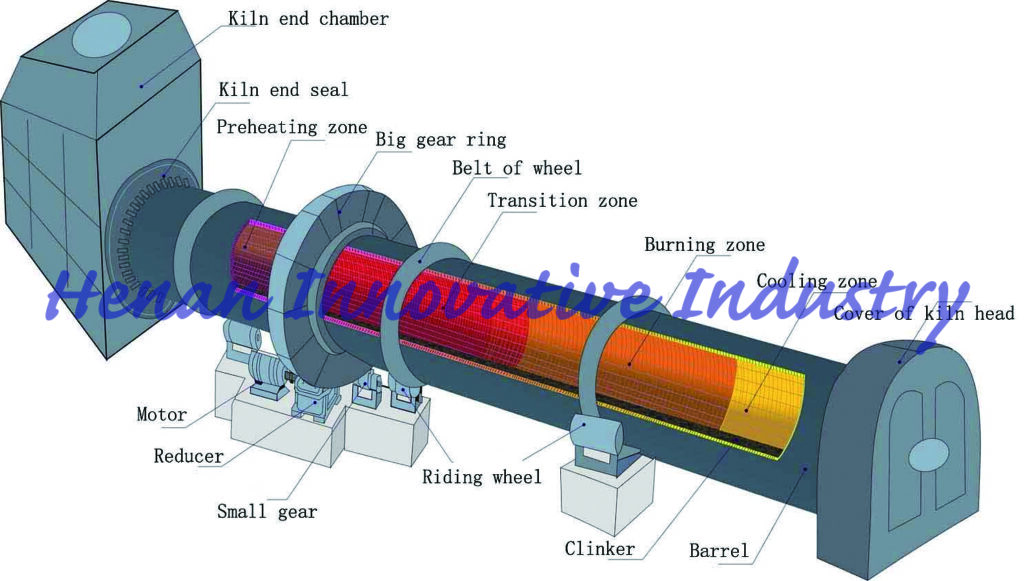

The Rotary Kiln is mainly consist of kiln shell, the refractory lining, support tyres (riding rings) and rollers, driving device, supporting device, thrust roller device, kiln head sealing device, kiln tail sealing device, kiln hood and fuel system components, drive gear and internal heat exchangers.

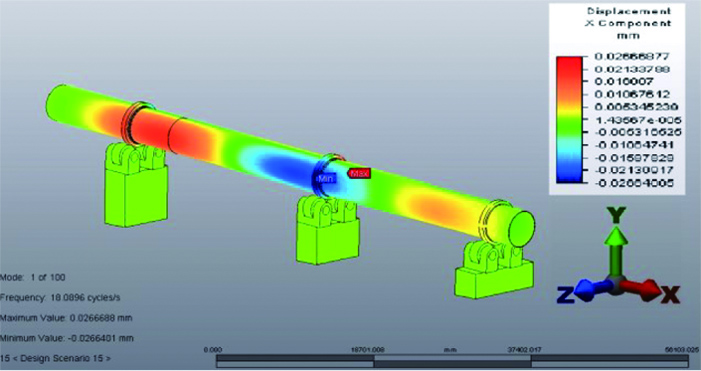

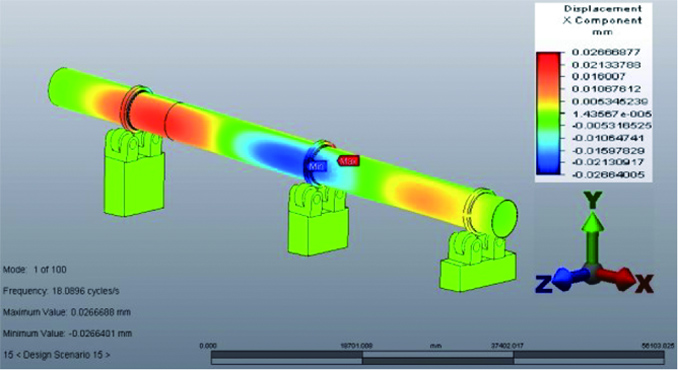

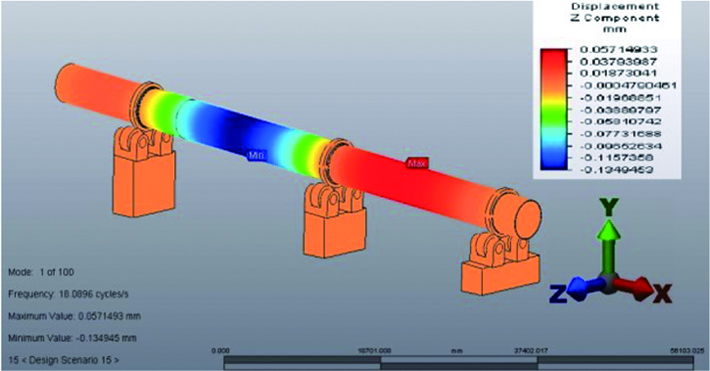

Vibration Analysis of Rotary Kiln Using Finite Element Method

X-axis

Y-axis

Z-axis

WORKING PRINCIPLE OF ROTARY KILN

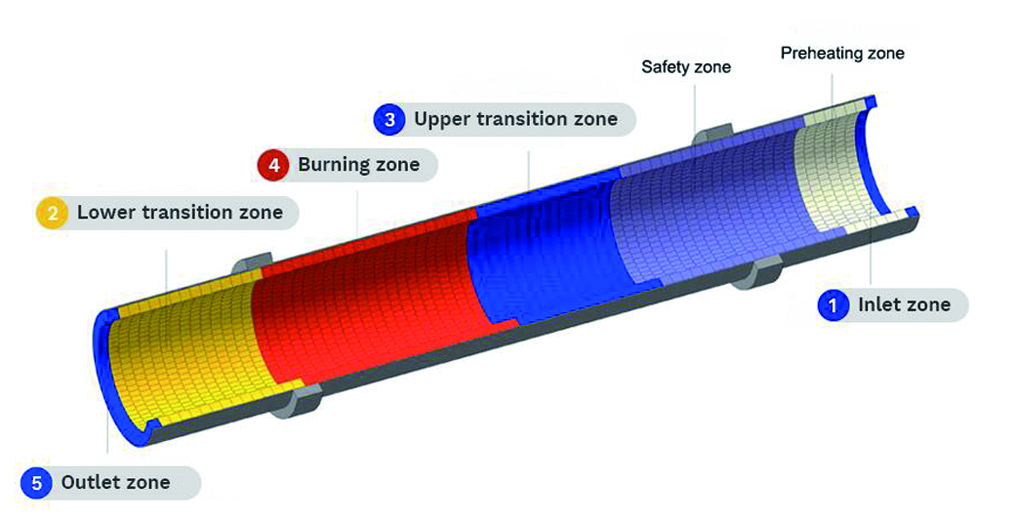

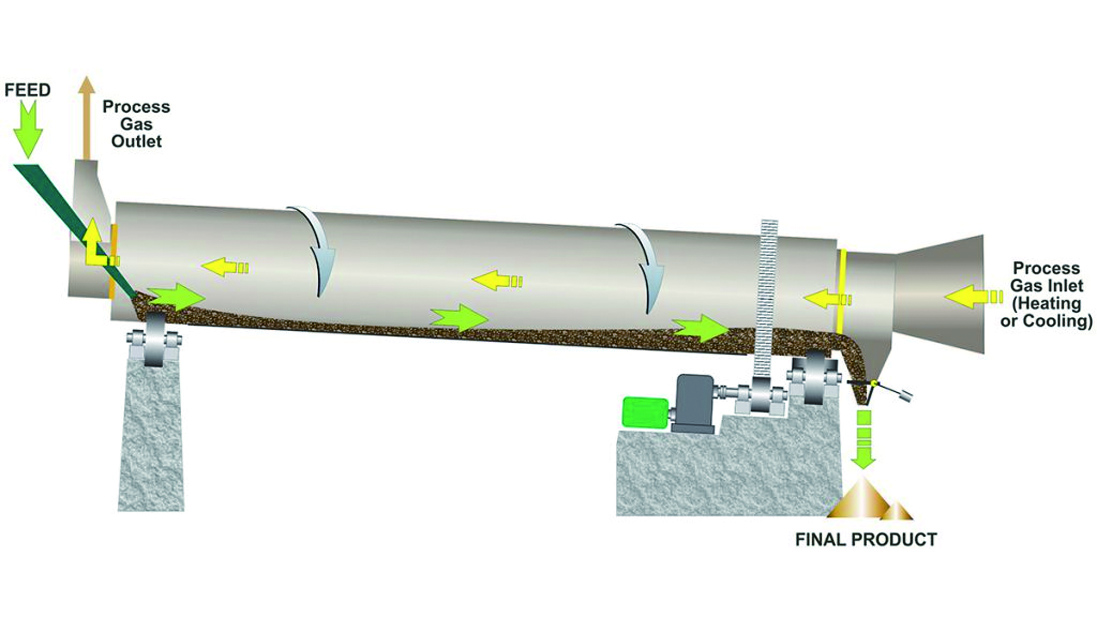

The rotary kiln consists of a tube made from steel plate, and lined with firebrick. The kiln is a cylindrical vessel, inclined slightly (1–5°) to the horizontal, which is rotated slowly about its longitudinal axis at between 30~250 revolutions per hour. The process feedstock is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down toward the lower end, and may undergo a certain amount of stirring and mixing.

Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current).

The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or “firing pipe”) which acts like a large bunsen burner. The fuel for this may be gas, oil, pulverized petroleum coke or pulverized coal.