Lime Calcination Plant

Introduction

Lime Calcination Plant is also known as quicklime plant, lime processing plant, lime production plant or quicklime production plant. Lime calcination plant is a complete quicklime production line to produce quicklime (also known as burnt lime) by calcination of limestone which contains mainly calcium carbonate. As quicklime or burnt lime is versatile material in industrial applications, many businessmen make forays into quicklime production plant.

However, to build a lime production plant with high efficiency needs professional knowledge as well as reliable lime processing machinery. Henan Innovative Industry has rich experience in designing and planning quicklime plant according to customer’s needs in capacity, end product quality and other requirements.

MANUFACTURING PROCESS

The main operation principle of quicklime production plant is the decomposition or calcination of limestone which contains mainly calcium carbonate. In the calcination process, when calcium carbonate is heated with high but appropriate temperature, the calcium carbonate decomposes into quicklime(CaO) and carbon dioxide(CO₂).

For the manufacturing process of quicklime plant, there are several stages: crushing, calcining, de-dusting and packing. As for the specific quicklime manufacturing processes, they are different in quicklime plant with rotary lime kiln and with vertical lime kiln.

QUICKLIME PLANT WITH ROTARY LIME KILN

In the lime processing plant with rotary lime kiln, it is advisable to add vertical preheater and vertical cooler. For the perheater can use the hot air from rotary lime kiln to heat the limestone so that some of the limestone can decompose. And then they are transported to the rotary lime kiln which can save energy to burn the limestone. For the cooler, it can cool the burnt lime to about 60C. So the process can be a little complex than the lime production line with vertical lime kiln.

Firstly, the sifted limestone of required sizes is transferred to the silo in pre-heater by belt conveyor. Then in the pre-heater, the limestone is pre-heated to about 900 degrees, through which about 30%~40% of limestone will decompose. Then the preheated limestone is transferred to the heating rotary lime kiln. At the other end of rotary lime kiln, which is also material outlet, the energy material is put in though fire furnace. After the calcination process in rotary lime kiln, the burnt lime is transported to vertical cooler. Then the cooled quicklime will be transferred to product silo. Of course, to eliminate pollution, there are also dust collectors, pollutant air chimney.

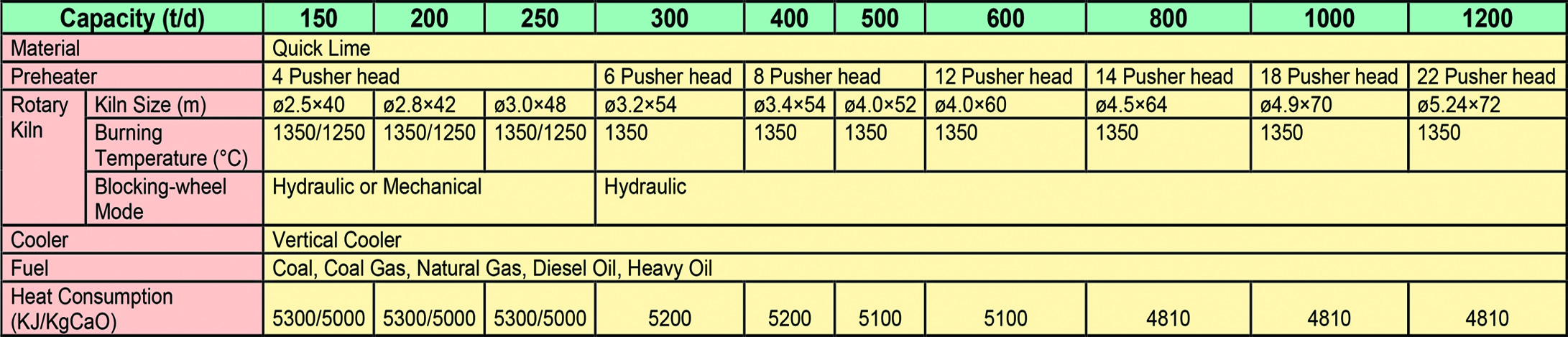

SPECIFICATION DATA