Jaw Crusher

Introduction

Application Fields: Metallurgy, Chemical, Building Materials, Electricity, Transportation and other Departments.

Jaw crusher is mainly used for the medium and fine crushing of hard ores and rocks in metallurgy industry, mining industry, chemical industry, cement industry, construction industry, refractory materials industry and ceramic industry and other sectors.

Processing capacity:

1-2200t/h

Finished size: 0-40mm

USAGE AND APPLICATION RANGE

01.

Jaw crusher is mainly used for the medium and fine crushing of hard ores and rocks in metallurgy industry, mine industry, chemical industry, cement industry, construction industry, refractory materials industry and ceramic industry and other sectors.

02.

Jaw crusher is suitable for crushing all kinds of hard and soft ores with less than 300MPa compressive strength, such as pebble, calcite, granite, quartz, concrete, dolomite, blue-stone, iron ore, limestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, ore, glass, cement clinker, etc.

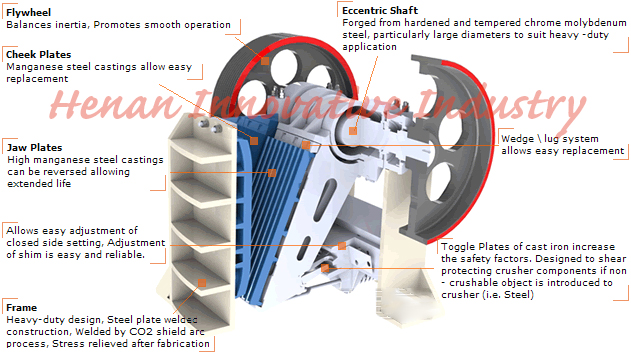

JAW CRUSHER STRUCTURE

WORKING PRINCIPLE OF JAW CRUSHER

Jaw crusher is composed of main frame, eccentric shaft, flying wheel, toggle plate, jaw plate, tension rod, fixed jaw, movable jaw and so on; among these parts the toggle plate can secure the whole body.

The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves. So, the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. The moving jaw of the crusher makes periodic crushing and discharging along with the motor to realized batch production.

TECHNICAL ADVANTAGES

01.

Movable jaw plate is made up of high-quality steel cast and moved through two big flywheels, which is more advanced and very durable.

02.

The crushing cavity is deep and do not have dead zone, which improves the feeding ability and capacity.

03.

The lubrication system is safe and reliable. It is easy to change the parts and maintain.

04.

The adjustment of discharging port is very big and meets various need of our customer. Gasket type of discharging port can strengthen the flexibility of jaw crusher and meets different manufacturing requirement.

05.

Simple structure, reliable work, strong crushing capacity, and easy maintenance.

06.

Jaw crusher adopts new tooth type of plate, which increases the length of jaw plate and improves the capacity.

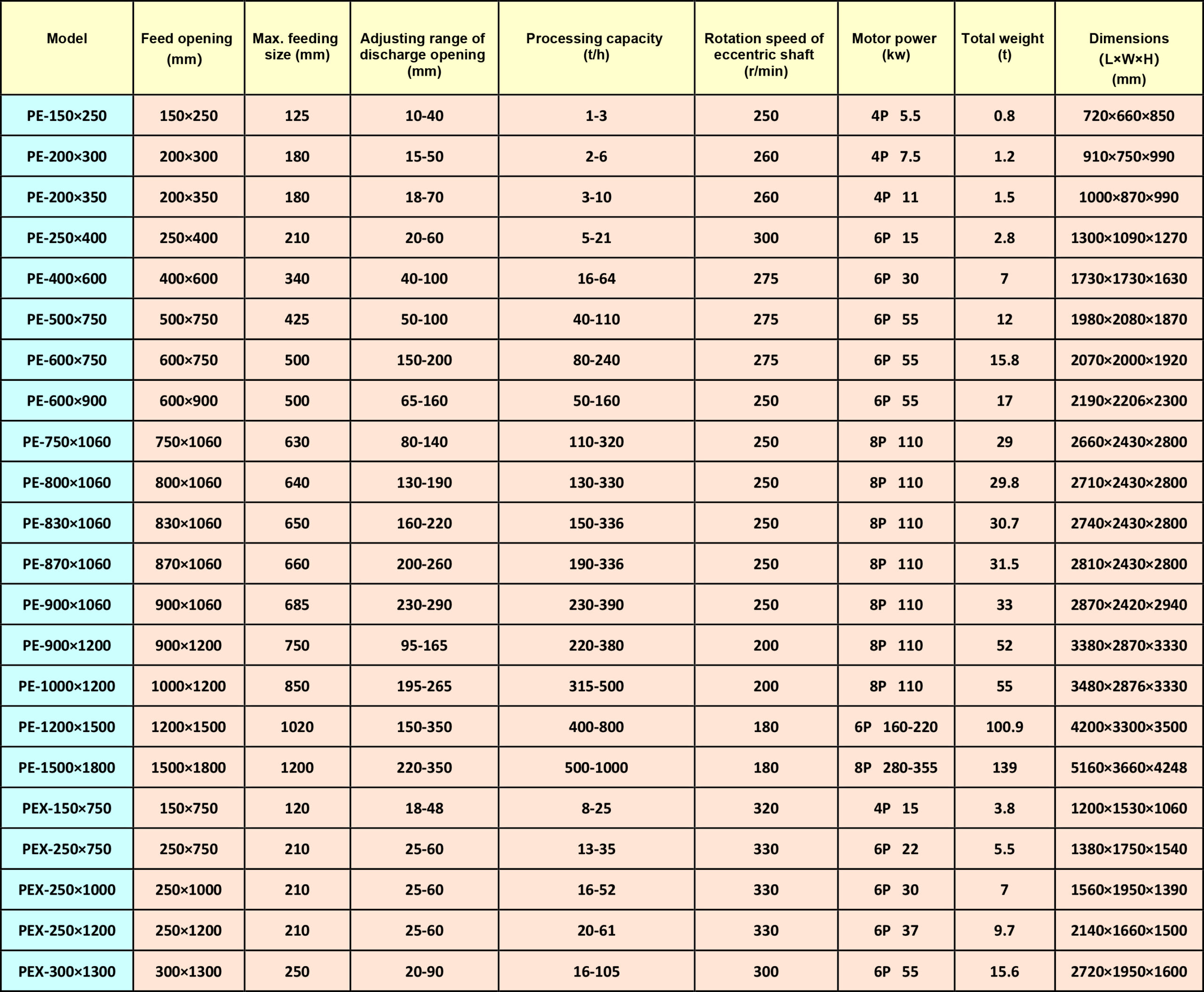

SPECIFICATION DATA