DMC Pulse Bag Dust Collector

Introduction

Application Fields: It can be widely used in industry of cement, electronics, chemicals, food processing, metallurgy, casting, carbon materials, machinery processing, wood and other building materials etc…

Application Range: De-dusting of calcium carbide furnace, dust removal of various electric furnaces in iron alloy factory; fuel gas purification of iron and steel plant; dust removal by coal-fired boiler and power plant small boiler; dust removal by garbage incinerator; fuel gas de-dusting of smelting plant; fuel gas purification of aluminum plant; tail gas de-dusting of carbon black plant .

Filter area : 24 ~ 84 m²

Resistance : ≤1200 pa

Inter dust concentration : <200 Nm³/min

Filtration Speed : 1.2 ~ 2.0 r/min

(Selection of different purification bag filtration speed according to different size dust particles)

A pulse-jet dust collector also known as pulse jet baghouse and pulse jet fabric filter refers to a dust collector using a pulse-jet cleaning system to remove the collected dust particles from the surface of the filter media by injecting high-pressure compressed air, with or without a venturi, into the top of the filter bags to backflush the filter bags vigorously.

DMC Pulse Dust Collector is suitable for dust removal and purification and material recovery of non-fibrous industrial dust in various working conditions. It has strong cleaning ability, long life filter bags, high dust removal efficiency, and low air leakage rate. Low consumption, small floor space, stable and reliable operation, and good economic benefits.

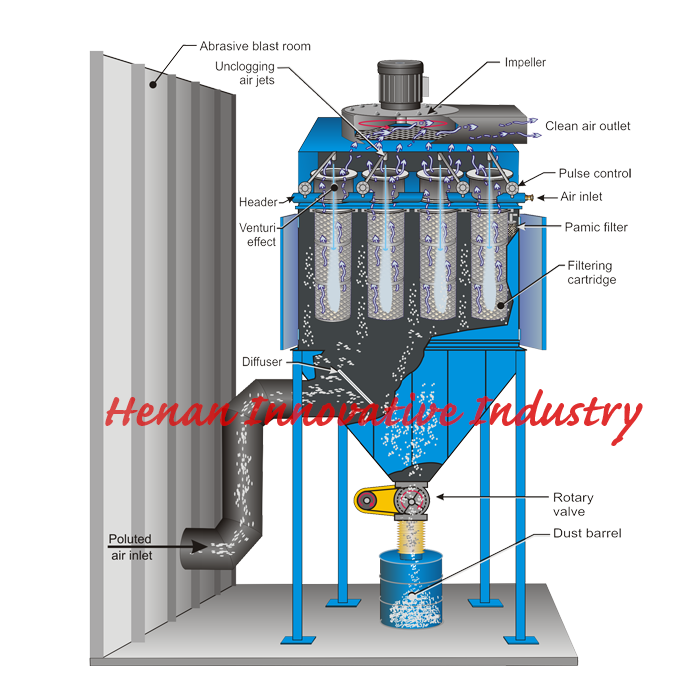

THE STRUCTURE AND WORKING PRINCIPLE OF DMC Pulse Dust Collector

The single-pulse dust collector is composed of net air chamber, the electromagnetic pulse valve, cylinder, air chamber, air chamber seal on the access door, enclosure, net gas outlet, outlet pipes, chimneys, air volume control valve, induced draft fan, the lower housing, closed air feeder, dust chamber, support leg, screw conveyor, pulse controller, storage tanks, re-flux valve, air compressor, pressure valve, compressed air, air inlet pipe, filter bag, air bag, air chamber raft, gas room bulkhead, pulse valve, etc.

DMC pulse bags filter makes the compressed air as the driving force for cleaning dust, the pulse injection organization releases the compressed air instantly and induces the secondary high-speed air into the filter bags to make the bags expand rapidly so as to shake off the dust and clean it.

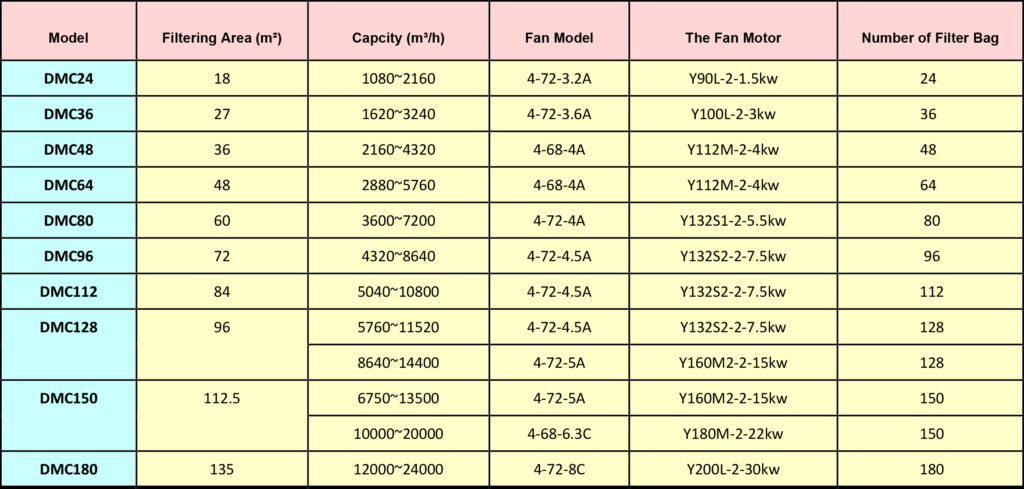

Series of the products: there are 24 bags, 36 bags, 48 bags, 60 bags, 72 bags, 84 bags, 96 bags, 108 bags, 112 bags and up to 180 bags.

SEQUENCE OF OPERATION

(1) Dust laden Air gas enters the dust collector through the inlet.

(2) Air passes through the filter media while solids are retained on the media’s surface.

(3) A signal from the timer actuates the opening of the normally closed solenoid valve.

(4) A momentary pulse of compressed air flows from the air header down the purge pipe and out into each filter bag. This momentary pulse takes all bags in one row off line through pressure reversal.

Features and advantages

(1) High dust collecting efficiency, low energy consumption.

(2) Filter bag with long service life as a result of new design dust collecting technology.