Cone Crusher

Introduction

Application Fields: Metallurgical Industry, Building Materials Industry, Road Construction Industry, Chemical Industry and Silicate Industry.

Applicable Materials: Quartz stone, river pebbles, calcite, dolomite, granite, basalt, iron ore, limestone, diabase, bluestone.

Processing capacity:

12 ~ 2200 t / h

Max. Feeding size: 35 ~ 300mm

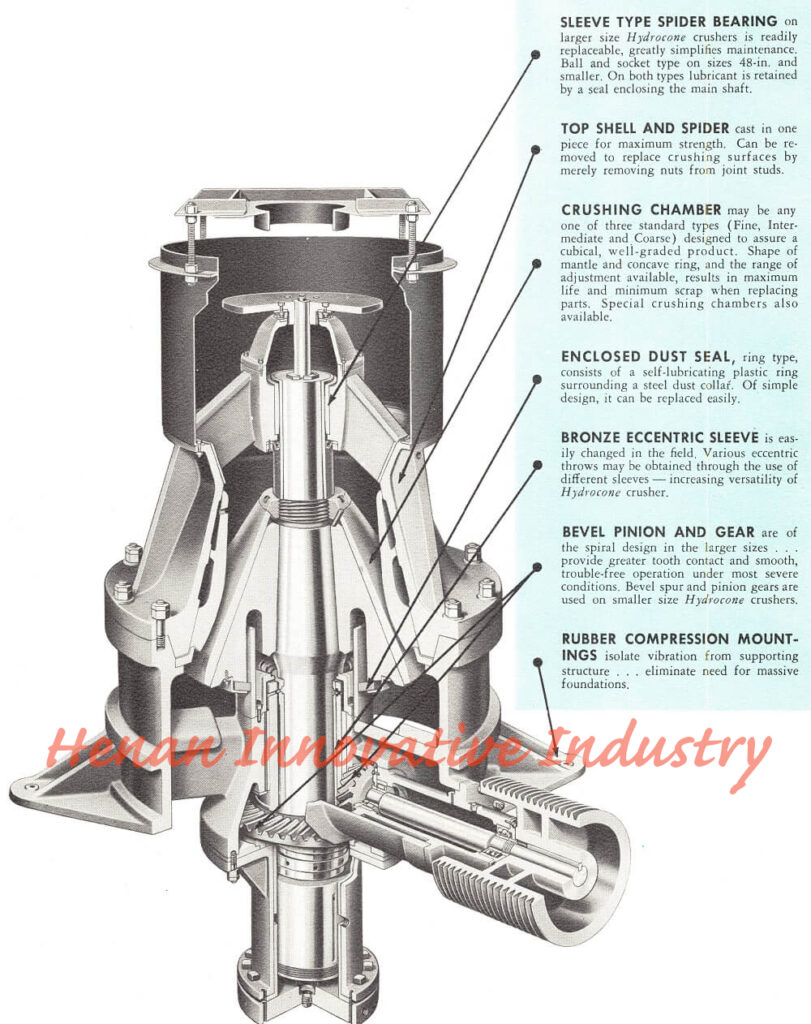

A cone crusher is generally used as a secondary crusher in a crushing process. Pre-crushed product is fed through the top of the cone crusher and flows over the mantle. The vertical cone crusher drive shaft rotates the mantle eccentrically below the concave, or bowl liner, squeezing the product and crushing it between the mantle and concave. Cone crushers are usually run on belt drives driven by an electric motor or diesel engine. Cone crushers are used extensively throughout the aggregate and mineral processing industry.

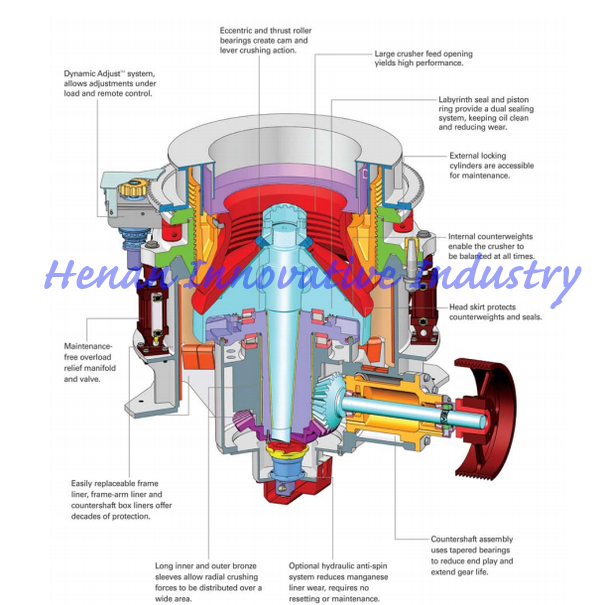

STRUCTURE & WORKING PRINCIPLE OF CONE CRUSHER

The working parts are two cutter heads, also called cones; one is fixed cone ( also called outer cone), the other one is movable cone ( also called inner cone). The outer cone is fixed, which is one part of frame; the movable cone is in the eccentric bush, so the central axis between the fixed cone and the movable cone intersects and forms into a bevel. When rotating, the movable cone rotates along the inner surface of the fixed cone. The place that the movable cone pressed against the fixed cone becomes the crushing cavity, where the materials is pressed, impacted and bent by the movable cone. The place that the movable moves away from the fixed cone becomes the discharging open, where the crushed materials are discharged out under the role of gravity.

TECHNICAL ADVANTAGES AND FEATURES

01.

Large Production Capacity and High Crushing Efficiency. Simple Structure, Easy to Maintain, Low Running Cost.

02.

Laminated Crushing Cavity, Uniform-sized, and Cubic Product, Low Energy Consumption.

03.

It has a compact structure and strong rigidness, and the rotor has big rotational inertia.A Variety of Cavity Types to Meet Various Demands in Granularity Types.

04.

Fully Automatic Control to Ensure Safe Operation of Equipment.

05.

The oil lubrication is durable and advanced and impact crusher has long lifetime.

06.

Cone crusher (usually preferred to spring cone crusher) has an overloading protection system that allows metal not to pass through the crushing chamber so as not to damage the cone crusher.

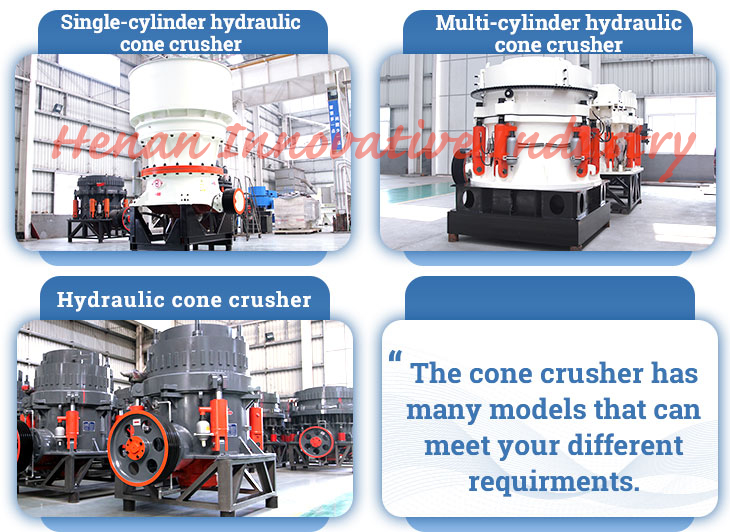

THE DIFFERENCE BETWEEN THE SINGLE-CYLINDER CONE CRUSHER AND THE MULTI-CYLINDER HYDRAULIC CONE CRUSHER.

The Comparison of Actual Production

Single-cylinder cone crushers

During normal operation, the oil pump is used to fill in or drain the spindle hydro-cylinder. In this way, the spindle will be moved up and down to adjust the discharge port size. This type of adjustment will be difficult for discharge port to lock when breaking the iron ores.

Multi-cylinder hydraulic cone crushers

Its main shaft tends to be short and thick, and its diameter is long. It can stand directly on the frame and directly be supported by the frame that provides high bearing capacity. The eccentric sleeve will directly drive the moving cone to provide the breaking force.

A Comparison of Crushing Components

Single-cylinder cone crushers

The single-cylinder hydraulic cone crusher is similar to the spring one. The main shaft and the moving cone are combined and carried by the bowl-shaped tile. Therefore, the main shaft and the moving cone will support the base, and the eccentric sleeve drives the main shaft to provide the crushing force.

Multi-cylinder hydraulic cone crushers

Adjusting the adjusting cap by hydraulic pusher or hydraulic motor can drive the adjusting ring to rotate in the support sleeve. In this way, the adjustment effect can be well achieved. The advantage of this type of adjustment is that the discharge port will be easy to lock.

The Comparison of Actual Production

When crushing the soft ores and weathered ores, the single-cylinder hydraulic cone is more outstanding. While when crushing the ores with medium and high hardness, the performance of multi-cylinder hydraulic cone breaking tends to be more excellent.

In the case of fine crushing for medium and high hardness, multi-cylinder cone crushers for sale can produce more qualified products under the same specifications. Generally speaking, the higher the hardness, the difference between the two types will be greater.

The Comparison of Maintenance

The single cylinder cone crusher has a simple structure and reliable performance, which means it has a low failure rate and low production cost (the simpler the mechanical system structure, the failure rate will be lower, and the reliability will be higher).

The top or side of the multi-cylinder cone crushers can be disassembled and assembled, and the repair is quick and convenient: all the parts can be disassembled and maintained from the top or the side, and the moving cone and the top cone can be easily disassembled without disassembling the frame and fastening bolts, so the daily replacement will be more convenient.

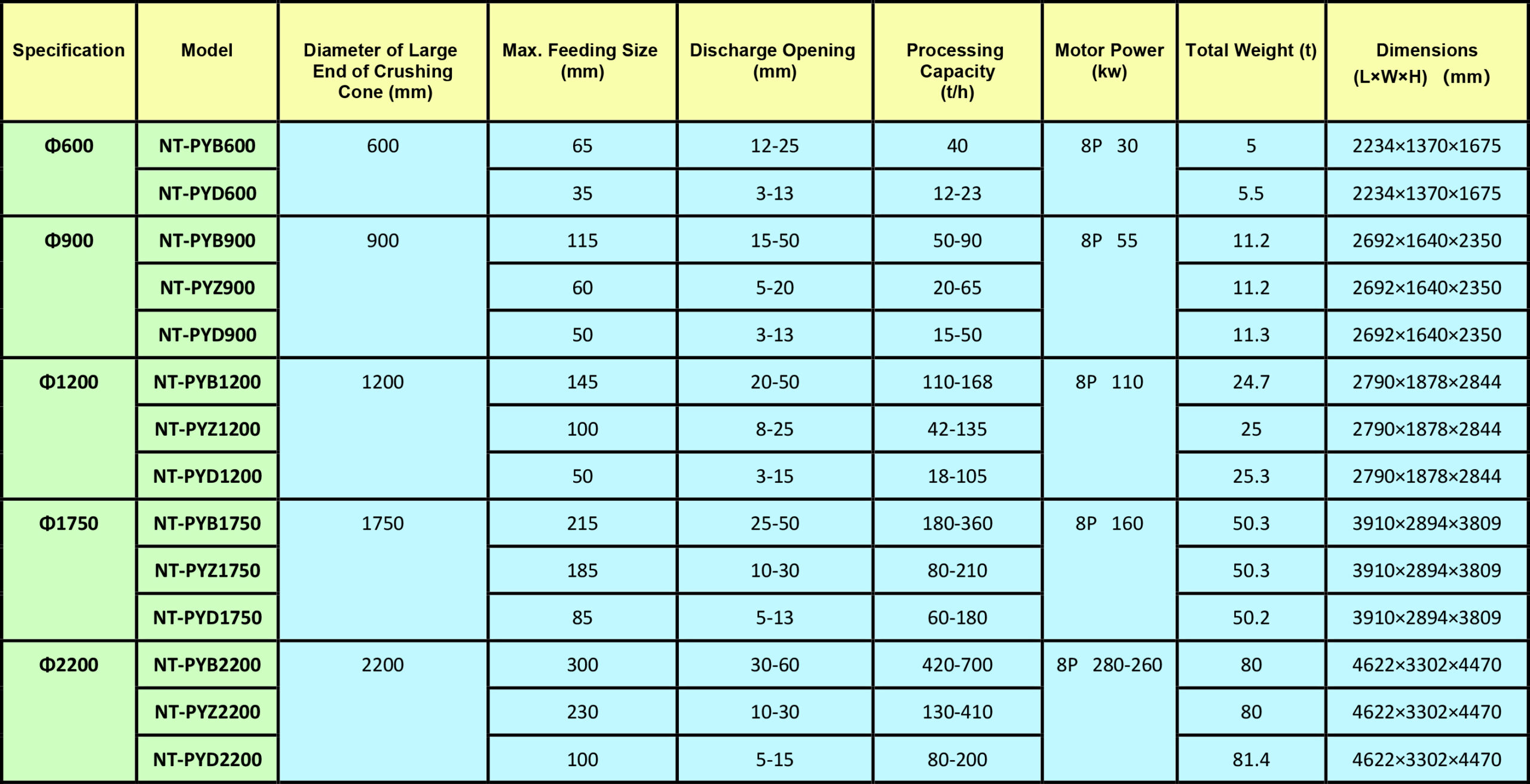

SPECIFICATION DATA