ADW Series Turbine Ultra-Fine Classifier

FEATURES & CHARACTERS

(1) Low energy consumption with high output.

(2) Using the design of strong turbine classify principle, the classifier impeller is placed horizontally, the structure has multiple impellers and single impeller.

(3) High precise particle size cutting, high clarity powder without rough powder.

(4) The fineness of the product can be adjusted arbitrarily through adjusting the rotation speed of the classifier impeller, it is simple and convenient to operate.

(5) Independent classifying system can be set up and used separately. It is more suitable to work directly with all kinds grinding equipment (such as ball mill, impact mill, vibration mill, vertical mill, airflow mill, stirring mill) to form a closed-circuit continuous ultra-fine production system.

(6) Wide applicability, it can be used in processing of various non-metallic mineral powder (such as calcite, kaolin and talc), ceramics, medicine, pesticides, abrasives and various inorganic and organic powders, etc.

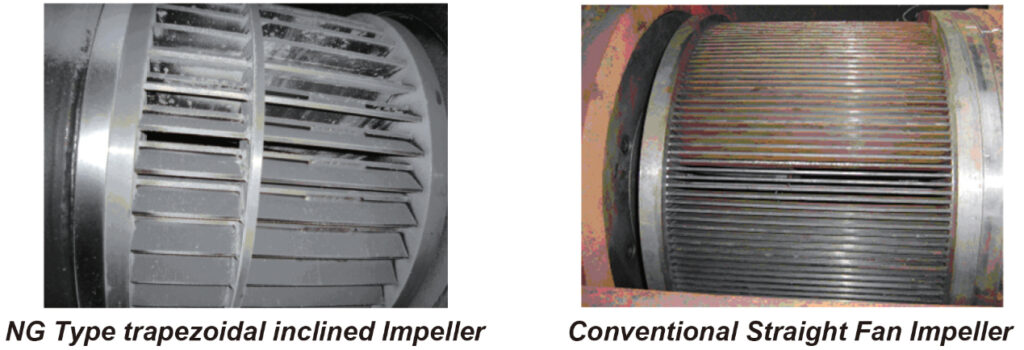

INTRODUCTION OF CLASSIFIER IMPELLER

According to the latest International NG technology, the classifying impeller made of backward bending & folding and trapezoidal combined blades, it has the following outstanding advantages.

(1) It’s easy to classify 5μm superfine powder with large diameter impellers, but it’s difficult for conventional impellers to do so.

(2) Compared with conventional impeller, the back pressure of classifier is reduced more than 30% and the energy consumption of blower is reduced by 20%-30%.

(3) D100 particle size of classifying powder is decreased by 2-3μm.